Concrete slab floors are cold. Really cold. They suck heat from your home and make your energy bills soar. But here’s the good news: proper floor insulation over concrete slab can solve this problem permanently.

Installing insulation over your concrete floor will cut heat loss by up to 20%, reduce energy bills, eliminate cold spots, and make your home comfortable year-round. The best part? It’s a job most homeowners can tackle themselves.

This guide covers everything you need to know about insulating concrete floors, from choosing the right materials to step-by-step installation.

Why Concrete Slabs Need Insulation

Concrete conducts heat 40 times faster than wood. Without insulation, your concrete floor acts like a massive heat sink, constantly drawing warmth from your home.

The Real Cost of Uninsulated Concrete Floors

- Energy waste: Up to 20% of your home’s heat escapes through uninsulated floors

- Comfort issues: Cold floors make rooms feel chilly even when air temperature is normal

- Condensation problems: Temperature differences create moisture issues

- Higher bills: Your heating system works overtime to compensate for heat loss

Signs Your Concrete Floor Needs Insulation

- Floors feel cold to touch, even in summer

- Rooms above concrete slabs are hard to heat

- Condensation appears on floor surfaces

- Energy bills seem unusually high

- Carpets or flooring feel damp

Types of Insulation for Concrete Slabs

1. Rigid Foam Insulation

Best for: DIY installation, basement floors, garages

Rigid foam boards (PIR, PUR, or XPS) offer excellent thermal performance and moisture resistance.

Pros:

- High R-value per inch

- Moisture resistant

- Easy to cut and install

- Doesn’t compress over time

Cons:

- More expensive upfront

- Requires careful sealing at joints

2. Spray Foam Insulation

Best for: Professional installation, irregular surfaces

Polyurethane spray foam creates an airtight seal and excellent insulation layer.

Pros:

- Perfect air seal

- Highest R-value available

- Fills gaps completely

- Adds structural strength

Cons:

- Requires professional installation

- Expensive

- Cannot be DIY project

3. Insulation Boards with Integral DPM

Best for: New builds, major renovations

These combine insulation and damp-proof membrane in one product.

Pros:

- Solves insulation and moisture in one step

- Faster installation

- Guaranteed compatibility

Cons:

- Limited thickness options

- More expensive than separate systems

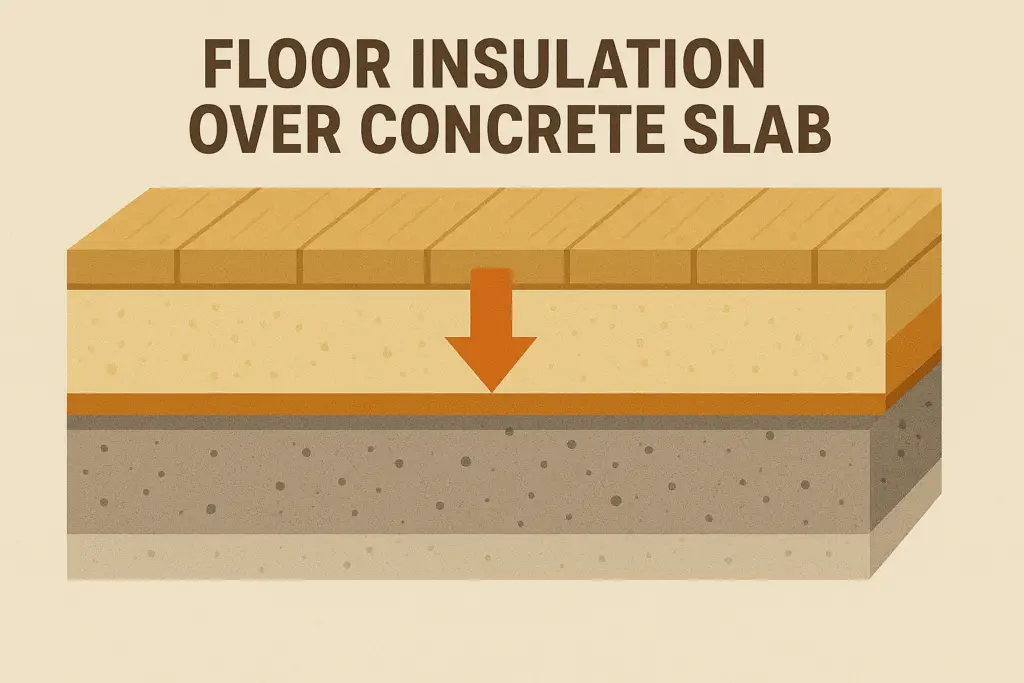

Step-by-Step Installation Guide

Tools and Materials Needed

Tools:

- Sharp utility knife

- Measuring tape

- Spirit level

- Trowel or screed board

- Mixing bucket

- Safety equipment (gloves, goggles, dust mask)

Materials:

- Insulation boards (PIR/PUR recommended)

- Damp-proof membrane

- Sand and cement for screed

- Adhesive (if required)

- Sealing tape

- Vapour control layer

Step 1: Prepare the Concrete Slab

Clean the slab thoroughly. Remove all debris, oil stains, and loose concrete. The surface must be level within 5mm over 3 metres.

Fill any cracks or holes with concrete repair compound. Allow to cure completely before proceeding.

Step 2: Install Damp-Proof Membrane

Lay polythene sheeting across the entire floor area. Overlap joints by 150mm and seal with waterproof tape.

The DPM prevents ground moisture from reaching your insulation and causing problems later.

Step 3: Lay Insulation Boards

Start from one corner and work systematically across the floor. Butt joints tightly together – gaps reduce thermal performance significantly.

For 100mm thick boards:

- Measure and cut boards with sharp knife

- Lay in brick-bond pattern for strength

- Ensure boards sit flat with no rocking

Step 4: Seal Joints and Perimeter

Use foil tape to seal all joints between boards. Pay special attention to perimeter gaps where boards meet walls.

Any thermal bridge will create cold spots and reduce overall performance.

Step 5: Add Vapour Control Layer

Lay another polythene sheet over the insulation. This prevents moisture from the screed reaching the insulation.

Overlap joints by 150mm and tape securely.

Step 6: Install Floor Screed

Mix sand and cement screed to 4:1 ratio. Add fibres to prevent cracking.

Pour and level to create smooth surface for final flooring. Minimum thickness: 65mm for foot traffic, 75mm for furniture.

Insulation Thickness Guide

| Room Type | Minimum Thickness | Recommended Thickness | R-Value Target |

|---|---|---|---|

| Living areas | 75mm | 100mm | 4.5 m²K/W |

| Bedrooms | 75mm | 100mm | 4.5 m²K/W |

| Kitchens | 50mm | 75mm | 3.5 m²K/W |

| Utility rooms | 50mm | 75mm | 3.5 m²K/W |

| Garages | 25mm | 50mm | 2.5 m²K/W |

Building Regulations Part L requires minimum 0.25 W/m²K for floor insulation in new builds. This typically means 100mm of quality insulation.

Common Mistakes to Avoid

1. Skipping the Damp-Proof Membrane

Moisture will destroy insulation performance and create mould problems. Always install proper DPM, even if concrete seems dry.

2. Leaving Gaps Between Boards

Even small gaps create thermal bridges that dramatically reduce performance. Measure carefully and cut precisely.

3. Insufficient Edge Insulation

Heat escapes around perimeters. Extend insulation up walls by at least 150mm or install perimeter insulation strips.

4. Wrong Insulation Type

Not all insulation suits concrete floors. Fibreglass batts compress and lose effectiveness. Stick to rigid boards designed for floor applications.

5. Poor Joint Sealing

Unsealed joints allow air movement that reduces thermal performance. Tape all joints with appropriate sealing tape.

Cost Breakdown

Material Costs (Per m²)

| Component | Budget Option | Mid-Range | Premium |

|---|---|---|---|

| Insulation boards | £8-12 | £15-20 | £25-35 |

| DPM | £1-2 | £2-3 | £3-5 |

| Screed materials | £3-5 | £5-8 | £8-12 |

| Sealing materials | £1-2 | £2-3 | £3-4 |

| Total per m² | £13-21 | £24-34 | £39-56 |

Labour Costs

- DIY: Just material costs

- Professional installation: £15-25 per m²

- Complete job (materials + labour): £35-65 per m²

When to Call Professionals

Consider professional installation if:

- Floor area exceeds 50m²

- Significant level differences exist

- Electrical or plumbing runs through floor

- Building regulations approval needed

- You’re uncomfortable with any step

Professional installation typically costs 40-60% more than DIY but includes guarantees and building control compliance.

Building Regulations and Planning

England and Wales

Building Regulations Part L applies to:

- New builds

- Extensions over 10m²

- Material changes of use

Minimum requirements:

- Floor U-value: 0.25 W/m²K maximum

- Continuity with wall insulation

- Proper vapour control

Scotland

Similar requirements under Section 6 of Building Standards, with slightly different U-value targets.

Planning Permission

Floor insulation rarely needs planning permission, but check with local authority if:

- Property is listed

- Located in conservation area

- Work affects building’s external appearance

Maintenance and Longevity

Expected Lifespan

Quality rigid foam insulation lasts 25-40 years without performance degradation. Properly installed systems require minimal maintenance.

Signs of Problems

- Cold spots developing

- Condensation on floor surfaces

- Musty odours

- Visible moisture damage

Preventive Maintenance

- Check perimeter seals annually

- Ensure good ventilation

- Address any water leaks immediately

- Monitor indoor humidity levels

Alternative Solutions

Insulated Floor Panels

Pre-made panels combine insulation, structural deck, and vapour control. Faster installation but higher cost.

Best for: Large areas, commercial applications

Electric Underfloor Heating

Can be combined with insulation for ultimate comfort. Install heating elements in screed layer above insulation.

Benefits: Precise temperature control, efficient heating, luxury feel

Floating Floor Systems

Insulation boards with tongue-and-groove edges create raised floor without screed.

Pros: No drying time, immediate installation of final flooring Cons: Raised floor level, hollow sound

Frequently Asked Questions

How thick should floor insulation over concrete slab be?

100mm thickness provides excellent performance for most homes. This achieves around 4.5 m²K/W thermal resistance, meeting current building standards with margin for future regulations.

Can I install floor insulation myself?

Yes, if you’re reasonably handy with tools. The process requires attention to detail but no special skills. Budget 2-3 days for average room, including drying time for screed.

What’s the best insulation material for concrete floors?

PIR (polyisocyanurate) boards offer the best balance of performance, cost, and ease of installation. They provide high R-values, resist moisture, and cut easily with standard tools.

Do I need planning permission for floor insulation?

Usually no, unless your property is listed or in a conservation area. Building regulations may apply for major renovations or extensions.

How much will floor insulation save on energy bills?

Properly insulated concrete floors typically reduce heating costs by 15-20%. For average UK home spending £1,200 annually on heating, savings of £180-240 per year are realistic.

Can I lay laminate directly on insulated concrete?

No, always install proper screed layer first. Direct laying on insulation boards creates uneven surface and potential damage to boards.

What if my concrete floor is damp?

Address dampness before insulating. Use tanking systems for serious damp problems. Minor moisture requires proper DPM installation as described in this guide.

How long before I can walk on newly insulated floor?

After screed installation, wait 24-48 hours for light foot traffic. Allow 7-14 days before installing final flooring, depending on screed thickness and conditions.

Conclusion

Floor insulation over concrete slab transforms cold, uncomfortable rooms into warm, efficient spaces. The investment pays for itself through reduced energy bills while dramatically improving comfort.

The key to success lies in proper preparation, choosing quality materials, and paying attention to detail during installation. While the initial cost might seem significant, the long-term benefits make it one of the best home improvements you can make.

Whether you tackle the job yourself or hire professionals, proper floor insulation will serve your home well for decades to come. Start planning your project today – your feet (and energy bills) will thank you.

For additional guidance on building regulations and technical specifications, consult the UK Government’s planning portal or speak with your local building control office.

Remember: good insulation is an investment in your home’s future comfort and efficiency. Done right, it’s a job you’ll only need to do once.