Get accurate measurements for your screed project with our easy-to-use screed calculator. Save time and money with our convenient online tool.

Floor Screed Calculator

Enter the dimensions of your floor and the desired thickness of the screed to calculate the amount of screed you need.

Other Tools For You:

- Sand, Cement Screed Calculator

- Self Leveling Screed Calculator

- Concrete Calculator UK: Free Ready-Mix Estimator for Builders

- Sand Calculator: How Much Sand Do I Need?

Screed Floor Thickness Load Capacity

| Screed Thickness (mm) | Light Load (≤ 2 kN/m²) | Medium Load (≤ 5 kN/m²) | Heavy Load (≤ 10 kN/m²) | Very Heavy Load (≤ 20 kN/m²) |

|---|---|---|---|---|

| 25 – 30 | ✔️ | ✔️ | ||

| 30 – 40 | ✔️ | ✔️ | ✔️ | |

| 40 – 50 | ✔️ | ✔️ | ||

| 50 – 70 | ✔️ | ✔️ |

Feedback from Our Users:

What is Screed Calculator?

A screed calculator is a tool that helps calculate the amount of screed (a thin layer of concrete or other material) needed for a specific area or project. It typically takes into account factors such as the size of the area, the thickness of the screed, and the type of screed being used. The calculator can help builders and contractors ensure they have the correct amount of materials on hand for the job and can also assist in budgeting and planning.

Screed Material Comparison Table:

Sand and Cement Screed Calculator

To calculate the amount of sand and cement needed for a screed, you will need to know the total area of the screed in square meters, as well as the thickness of the screed in millimeters.

Once you have this information, you can use the following formula to calculate the amount of sand and cement needed:

Formula

(Area of screed in sq m) x (Thickness of screed in mm) x (Cement:Sand ratio) = Total amount of cement and sand required in kg

For example, if you are screeding a floor with an area of 100 square meters and a thickness of 50mm and the ratio of cement to sand is 1:5 then the total amount of cement and sand required would be: 100 x 50 x (1+5) = 6000 kg

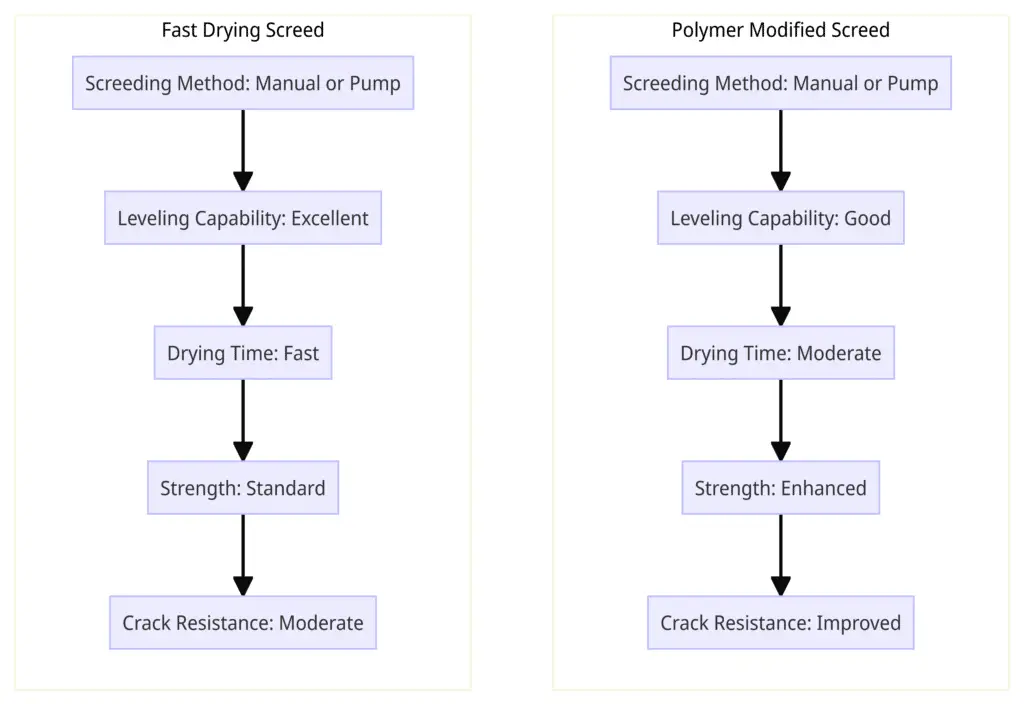

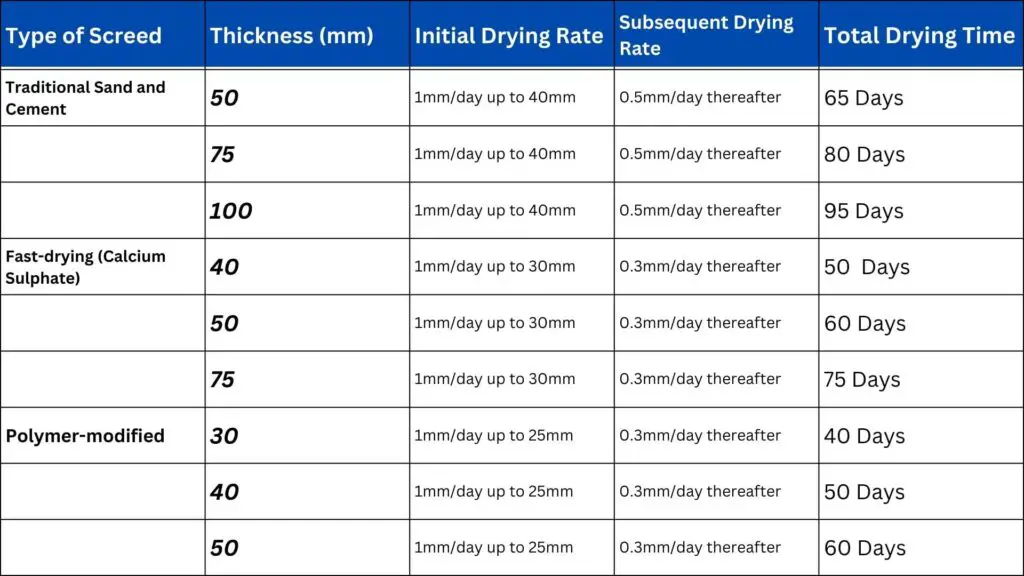

How do you estimate drying times?

We use researched benchmarks on drying rates for various screed types and thicknesses. We also account for common on-site conditions like underfloor heating and ventilation to provide realistic time estimates.

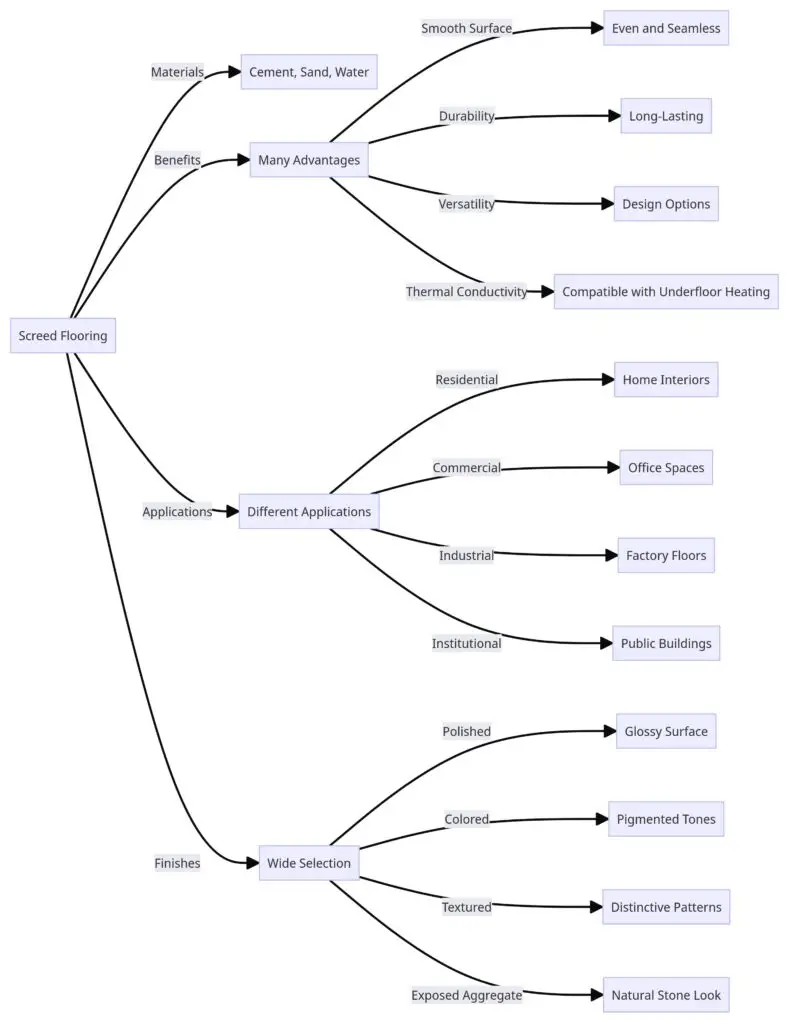

Screed Flooring Applications

FAQs

How much screed do I need?

In order to determine how much screed you need, you will need to know the dimensions of the area where the screed will be applied (length, width, and depth) and the desired thickness of the screed layer. Once you have this information, you can calculate the total volume of screed needed by multiplying the area by the desired thickness.

For example, if the area is 10 feet by 20 feet and the desired thickness is 1 inch, the total volume of screed needed would be:

10 ft x 20 ft x 1 inch = 200 sq ft x 1 inch = 200 cubic feet

It’s always a good idea to add extra to your estimate to make sure you have enough.

What is Latex screed?

Latex screed is a type of flooring material used to create a smooth and level surface on a concrete or other subfloor. It is made from a mixture of latex, cement, and sand, and is typically applied in a thin layer (typically around 2-3 mm thick) using a trowel or other spreading tool.

Once applied and allowed to dry, latex screed creates a durable and hard-wearing surface that is resistant to wear and tear and can be easily cleaned and maintained. It is often used in high-traffic areas such as commercial buildings, hospitals, and schools.

How long does screed take to dry?

The drying time for screed can vary depending on several factors such as the thickness of the screed, the type of screed used, the ambient temperature and humidity, and the ventilation in the room. Typically, screed can take between 24-48 hours to dry, but it can take up to 7 days for thicker layers or in adverse conditions. It is important to allow the screed to dry thoroughly before applying any floor coverings or walking on it.

How much to screed a floor?

The cost to screed a floor can vary depending on a number of factors, such as the size of the area to be screeded, the type of screed being used, and the location of the project. On average, the cost to screed a floor ranges from £2.5 to £10 per square foot. However, it is best to get a quote from a professional contractor for an accurate estimate for your specific project.

How long does it take to screed a floor?

The time it takes to screed a floor will depend on a number of factors, including the size of the area to be screeded, the type of screed being used, and the skill level of the person performing the screeding. On average, it may take several hours to a full day to screed a typical residential floor. It’s important to keep in mind that screeding is a critical step in the flooring process and it’s important to take the necessary time to do it properly to ensure a smooth and level surface.

How long for screed to dry before karndean?

The drying time for screed before laying Karndean flooring can vary depending on several factors such as the thickness of the screed, the humidity and temperature of the room, and the type of screed used. As a general rule, screed should be left to dry for at least 24 hours for every 1 cm of thickness before the installation of flooring. Therefore, for a 3 cm thick screed, it should be left to dry for at least 72 hours.

Can you screed over screed?

Yes, it is possible to screed over screed. However, it is important to ensure that the existing screed is level and in good condition before applying the new layer. The new screed should be applied at the correct thickness and allowed to dry properly before any flooring is laid on top.

How to dry screed quickly?

There are a few methods for speeding up the drying process of screed:

- Increasing ventilation in the area where the screed is laid can help to dry it more quickly.

- Using a dehumidifier can also help to remove moisture from the air, which can speed up the drying process.

- Using a heating system such as underfloor heating can also help to dry screed more quickly.

- Using a dry accelerator, a chemical added to the screed mix to accelerate the setting time, can also be used.

- Reduce the thickness of the applied screed layer.

Is latex floor screed waterproof?

Latex floor screed is not inherently waterproof. However, it can be made waterproof by applying a waterproofing membrane on top of it before applying the final flooring. This can be done by applying a liquid membrane or by using a sheet membrane that is laid on top of the screed and then sealed at the edges. It is important to make sure that the screed is fully cured before applying the waterproofing membrane.

What is Mapei renovation screed?

MAPEI Renovation Screed is a self-leveling screed used for leveling and smoothing concrete surfaces before installing flooring. It is designed for use on interior concrete surfaces and can be applied over existing tile, carpet, and other flooring materials.

The product is easy to use and can be applied with a trowel or squeegee. It dries quickly and can be walked on in as little as 3 hours and be ready for tile installation in as little as 24 hours. It’s also designed to be used in conjunction with underfloor heating systems.

What is floor screeding?

Floor screeding is the process of leveling and smoothing the surface of a concrete floor before the installation of flooring materials such as tile, hardwood, or carpet. Screeding is a critical step in the installation of many types of flooring, as it ensures that the final surface will be level and free of imperfections that could affect the performance or appearance of the finished floor.

Minimum screed thickness

The minimum screed thickness typically varies depending on the type of screed and the application. For example, for a sand and cement screed on a floor, a minimum thickness of 50mm is generally recommended, while for an insulated screed on a floor, a minimum thickness of 75mm is typically required.

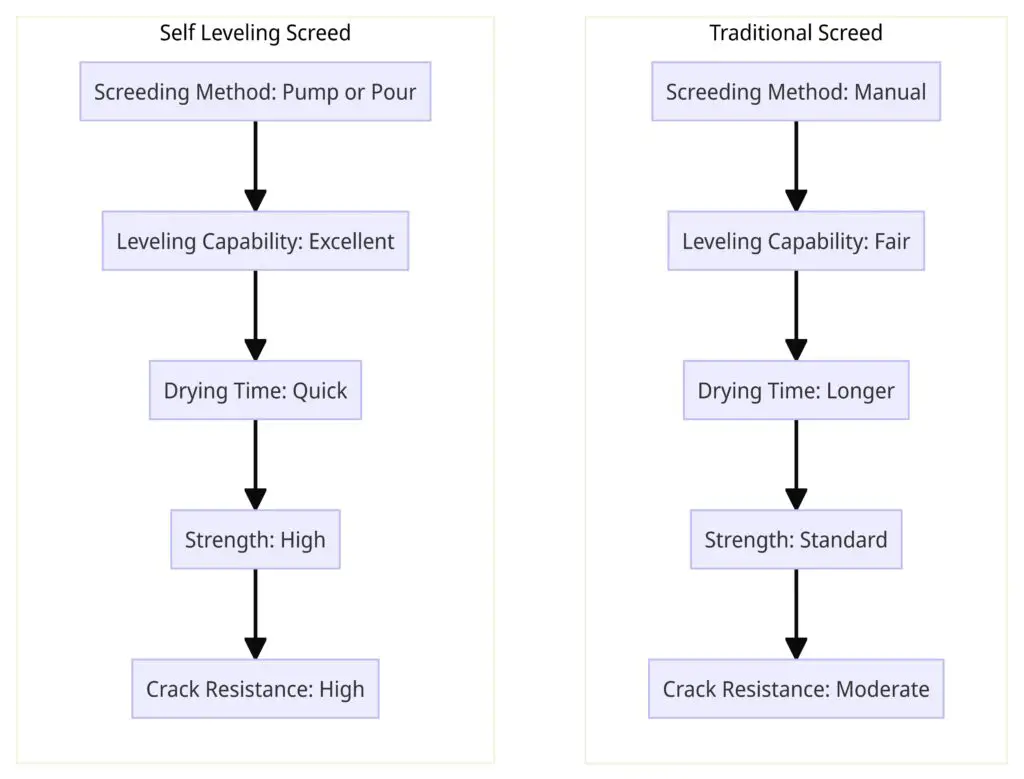

What are some types of screed?

There are several types of screeds that are used in construction, including:

1.Traditional screed

It’s a straight piece of wood or metal used to level and smooth concrete surfaces.

2.Power screed

A motorized screed that uses a vibrating blade to level and smooth concrete surfaces.

3.Truss screed

The screed that is supported by an adjustable truss system, allowing for the leveling of large concrete surfaces.

4.Laser screed

Screed that uses a laser guidance system to ensure precise leveling of concrete surfaces.

5.Vibrating screed

A screed that uses vibration to settle and compact concrete, providing a smooth and level surface.

6.Strike-off screed

A screed that is used to level and smooth freshly placed concrete, typically in large flat-work projects.

These are the most common types of screeds. Depending on the project, the type of screed used can vary.

Flexible screed for wooden floors

A flexible screed for wooden floors is a type of leveling compound that can be used to smooth out and level uneven wooden sub-floors before installing new flooring. The flexibility of the screed allows it to move with the natural movement of the wood, preventing cracking or damage to the new flooring. It is typically applied with a trowel, and can be used with both solid and engineered wood flooring.

Self leveling screed

Self-leveling screed is a type of flooring material that is used to create a smooth and level surface on concrete floors. It is typically made from a combination of cement, aggregate, and a liquid polymer, and is applied as a liquid mixture that spreads evenly across the surface and then hardens to create a smooth, level surface.

Self-leveling screed is often used in commercial and industrial buildings, as well as in residential construction, to create a smooth surface for flooring materials such as tile, hardwood, or carpet.

Self leveling screed for garage floor

Self-leveling screed can be used on garage floors to create a smooth and level surface for the installation of various types of flooring materials such as epoxy coating, tile, or carpet. It is particularly useful for garage floors that have uneven or damaged surfaces, as it can fill in low spots and smooth out rough areas.

Self-leveling screed is applied as a liquid mixture that spreads evenly across the surface and then hardens to create a smooth, level surface. It is important to properly prepare the garage floor surface before applying the screed by cleaning, grinding or filling any cracks or holes, and ensuring that the surface is dry and free of debris.

It is also recommended to apply a sealant or a moisture barrier to prevent moisture coming through the concrete and to enhance the adhesion of the screed.