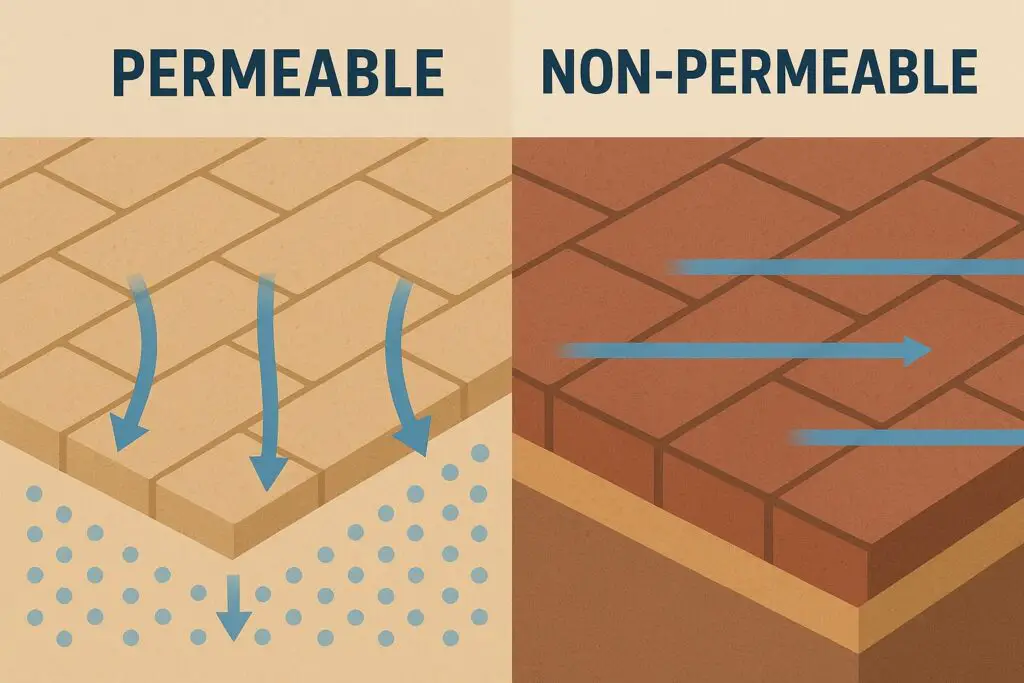

Choosing between permeable and non-permeable paving affects your property’s drainage, legal compliance, and long-term maintenance costs. Permeable paving allows water to pass through the surface into the ground below, whilst non-permeable paving creates an impermeable barrier that requires proper drainage systems.

This guide explains exactly what you need to know about both options, their costs, benefits, and when to use each type for your UK property.

What Is Permeable Paving?

Permeable paving systems allow rainwater to filter through the surface material into the ground beneath. The water passes through gaps between pavers, porous materials, or specially designed drainage channels.

These systems work by creating pathways for water to reach the soil naturally. This reduces surface water runoff and helps prevent flooding whilst recharging groundwater supplies.

How Permeable Paving Works

The system consists of several layers:

- Surface layer: Permeable blocks, porous asphalt, or gapped materials

- Bedding layer: Fine aggregate that supports the surface

- Sub-base: Coarse stone that stores water temporarily

- Sub-grade: The existing soil beneath

Water flows through each layer at different rates. The sub-base acts like a reservoir, slowly releasing water into the ground below.

What Is Non-Permeable Paving?

Non-permeable paving creates a waterproof surface that prevents water penetration. Common examples include traditional concrete, standard tarmac, and closely laid natural stone without drainage gaps.

These surfaces direct all rainwater to drainage systems like gutters, drains, or surface channels. Without proper drainage planning, water pools on the surface or runs off onto adjacent areas.

Key Differences Between Permeable and Non-Permeable Paving

| Feature | Permeable Paving | Non-Permeable Paving |

|---|---|---|

| Water drainage | Through surface into ground | Surface runoff to drains |

| Planning permission | Often not required | May require permission over 5m² |

| Installation cost | £40-120 per m² | £25-80 per m² |

| Maintenance | Regular cleaning required | Minimal maintenance |

| Lifespan | 20-25 years | 25-30+ years |

| Environmental impact | Reduces runoff and flooding | Increases surface water burden |

Types of Permeable Paving Systems

1. Permeable Block Paving

Concrete or clay blocks designed with gaps that allow water drainage. The gaps fill with jointing sand or gravel.

Best for: Driveways, car parks, pedestrian areas Cost: £50-90 per m² Pros: Attractive appearance, good load-bearing capacity Cons: Gaps can clog with debris over time

2. Porous Asphalt and Concrete

These materials contain voids that allow water to pass through the surface itself.

Best for: Large commercial areas, car parks Cost: £40-70 per m² Pros: Smooth surface, good for wheelchair access Cons: Can clog in high-debris areas

3. Gravel and Aggregate Surfaces

Loose stone materials that naturally allow water penetration.

Best for: Rural driveways, paths, temporary surfaces Cost: £25-50 per m² Pros: Low cost, easy installation Cons: Requires regular maintenance, not suitable for high traffic

4. Grass Paving Systems

Plastic or concrete grids filled with soil and grass that provide a load-bearing surface.

Best for: Overflow parking, fire access routes Cost: £35-65 per m² Pros: Green appearance, good for occasional use Cons: Requires lawn maintenance, not suitable for heavy daily use

Types of Non-Permeable Paving

Standard Block Paving

Traditional concrete or clay blocks laid with sand joints and sealed edges.

Best for: High-traffic driveways, decorative areas Cost: £35-75 per m²

Tarmac and Asphalt

Smooth bituminous surfaces that provide complete water resistance.

Best for: Large driveways, commercial surfaces Cost: £25-45 per m²

Concrete Slabs

Large format concrete or natural stone slabs laid on solid foundations.

Best for: Patios, formal entrances Cost: £30-80 per m²

UK Planning Permission and Legal Requirements

When You Need Planning Permission

Under UK Permitted Development Rights, you need planning permission for non-permeable surfaces over 5 square metres that don’t drain to a permeable area.

Permeable paving typically doesn’t require planning permission regardless of size, provided it meets drainage standards.

Building Regulations Compliance

All paving must comply with Building Regulations Approved Document H for surface water drainage.

Key requirements include:

- Adequate drainage capacity

- Connection to appropriate drainage systems

- Prevention of surface water discharge to neighbours’ property

Environmental Considerations

The Sustainable Drainage Systems (SuDS) guidance encourages permeable surfaces to reduce flood risk and protect water quality.

Local authorities may require SuDS compliance for larger developments or areas with flooding concerns.

Cost Comparison: Installation and Long-Term

Initial Installation Costs

Permeable paving: £40-120 per m² installed

- Higher material costs

- More complex sub-base preparation

- Specialist installation often required

Non-permeable paving: £25-80 per m² installed

- Lower material costs

- Standard installation techniques

- Wider availability of contractors

Long-Term Maintenance Costs

Permeable paving annual maintenance:

- Cleaning and debris removal: £2-5 per m²

- Sand joint replacement: £1-3 per m² (every 2-3 years)

- Weed treatment: £0.50-1.50 per m²

Non-permeable paving annual maintenance:

- Basic cleaning: £0.50-2 per m²

- Resealing (if required): £3-8 per m² (every 5-10 years)

- Minor repairs: £1-4 per m²

Total Cost Over 20 Years

Including installation and maintenance, permeable paving typically costs 15-25% more than non-permeable alternatives over a 20-year period.

Benefits of Permeable Paving

Environmental Advantages

- Reduces surface water runoff by up to 90%

- Helps prevent local flooding

- Filters pollutants from rainwater

- Recharges groundwater supplies

- Reduces strain on drainage systems

Property Benefits

- Often no planning permission required

- Adds environmental value to property

- Reduces need for additional drainage infrastructure

- Complies with sustainable development requirements

Practical Advantages

- Natural de-icing in winter (better drainage prevents ice formation)

- Reduces surface water pooling

- Can eliminate need for soakaways in suitable ground conditions

Benefits of Non-Permeable Paving

Durability and Performance

- Longer lifespan (25-30+ years typical)

- Better resistance to freeze-thaw damage

- Suitable for heavy vehicle loads

- Maintains appearance longer

Cost Advantages

- Lower initial installation cost

- Reduced ongoing maintenance requirements

- Wider choice of contractors and materials

- Established installation techniques

Practical Benefits

- Easier snow clearance

- Better for areas requiring frequent cleaning

- Suitable for steep slopes where drainage control is important

Disadvantages and Limitations

Permeable Paving Drawbacks

Maintenance Requirements

- Regular cleaning needed to prevent clogging

- Weeds can grow in gaps between pavers

- Sand joints require periodic replacement

- Professional maintenance may be needed

Performance Limitations

- Can become less effective over time if not maintained

- Not suitable for areas with high levels of fine sediment

- May freeze more readily in winter

- Limited colour and design options compared to sealed surfaces

Ground Condition Requirements

- Not suitable for clay soils with poor drainage

- Requires adequate sub-base depth

- May need geotextile membrane in some soil types

Non-Permeable Paving Drawbacks

Drainage Requirements

- Must provide alternative drainage solutions

- Can contribute to local flooding if poorly designed

- May require planning permission for large areas

- Creates additional burden on public drainage systems

Environmental Impact

- Increases surface water runoff

- Contributes to urban heat island effect

- Prevents natural groundwater recharge

- May require expensive drainage infrastructure

Choosing the Right Option for Your Project

When to Choose Permeable Paving

Ideal situations:

- Properties in flood-prone areas

- Areas over 5m² where planning permission would otherwise be required

- Environmentally conscious projects

- Sites with good natural drainage

- Areas where sustainable drainage is encouraged or required

Soil conditions that work well:

- Sandy or loamy soils

- Areas with good natural percolation

- Sites where groundwater level is below 1 metre

When to Choose Non-Permeable Paving

Ideal situations:

- Heavy-duty commercial or industrial use

- Areas requiring frequent cleaning (food preparation areas)

- Sites with poor natural drainage

- Projects with tight maintenance budgets

- Steep slopes where controlled drainage is essential

Soil conditions that work well:

- Clay soils with poor drainage

- Areas with high groundwater levels

- Sites where controlled water management is required

Installation Process and Requirements

Permeable Paving Installation

- Excavation: Dig to required depth (typically 400-600mm)

- Geotextile laying: Install separation membrane if required

- Sub-base preparation: Lay and compact coarse aggregate base

- Bedding layer: Add fine aggregate bedding material

- Paving installation: Install permeable pavers or surface material

- Jointing: Fill gaps with appropriate jointing material

Critical success factors:

- Proper sub-base depth and material specification

- Adequate compaction at each layer

- Correct fall gradients (typically 1:60 minimum)

- Quality jointing material that won’t wash out

Non-Permeable Paving Installation

- Excavation: Dig to required depth for intended use

- Sub-base preparation: Install and compact appropriate aggregate

- Edge restraints: Install permanent edge support

- Surface installation: Lay paving material according to specification

- Drainage connection: Connect to appropriate drainage system

- Sealing (if required): Apply sealant to joints and surface

Maintenance Requirements and Best Practices

Permeable Paving Maintenance

Monthly tasks:

- Remove leaves and debris from surface

- Check for standing water (indicates possible clogging)

- Clear any visible blockages in joints

Annual maintenance:

- Professional cleaning with vacuum equipment

- Weed treatment in joints

- Joint sand replacement where needed

- Check and clear edge drainage

Every 2-3 years:

- Complete joint renovation

- Surface deep-clean with pressure washing

- Inspect sub-base condition

Non-Permeable Paving Maintenance

Monthly tasks:

- Basic surface cleaning

- Check drainage outlets for blockages

- Remove weeds from expansion joints

Annual maintenance:

- Deep clean surface

- Inspect for cracks or settlement

- Clear all drainage connections

Every 5-10 years:

- Resealing (if applicable)

- Major crack repairs

- Drainage system maintenance

Common Problems and Solutions

Permeable Paving Issues

Problem: Surface clogging and reduced permeability Solution: Regular vacuum cleaning and joint sand replacement

Problem: Weed growth in joints Solution: Apply appropriate weed killer and maintain proper joint sand levels

Problem: Uneven settlement Solution: Remove affected area, improve sub-base, and reinstall

Problem: Winter ice formation Solution: Improve drainage, check for blockages, consider alternative de-icing methods

Non-Permeable Paving Issues

Problem: Surface water pooling Solution: Improve drainage falls, add additional drainage points

Problem: Cracking and deterioration Solution: Address underlying causes (settlement, freeze-thaw), repair or replace affected areas

Problem: Staining and discolouration Solution: Regular cleaning, appropriate cleaning products, consider protective sealers

Environmental Impact and Sustainability

Permeable Paving Environmental Benefits

Permeable surfaces significantly reduce the environmental impact of development:

- Flood reduction: Can reduce peak runoff rates by 60-100%

- Water quality: Filters pollutants including oils, heavy metals, and sediments

- Urban heat island effect: Reduces surface temperatures through evaporation

- Biodiversity: Some systems support plant growth and insect habitats

Carbon Footprint Considerations

Material production: Permeable systems often use similar materials to conventional paving but may require additional aggregates for sub-base construction.

Transport: Local sourcing of aggregate materials can reduce transport emissions.

Lifespan: Shorter lifespan of some permeable systems may increase lifetime carbon footprint through replacement cycles.

Operational benefits: Reduced need for drainage infrastructure and flood management can offset higher initial carbon footprint.

Regional Considerations Across the UK

England

Most areas follow standard Building Regulations and permitted development rights. Areas with flood risk may have additional requirements for sustainable drainage.

Scotland

Scottish Building Standards may have different requirements. Check with local authorities about SuDS requirements.

Wales

Welsh Government promotes sustainable drainage systems. New developments over certain sizes require SuDS approval.

Northern Ireland

Building Regulations may vary from other UK regions. Check local planning requirements with district councils.

Future Trends and Innovations

Smart Permeable Systems

New technologies include:

- Sensors monitoring drainage performance

- Self-cleaning surface materials

- Enhanced filtration capabilities

- Integration with smart city water management

Climate Change Adaptation

Increasing rainfall intensity makes permeable paving more valuable:

- Higher capacity systems for extreme weather

- Improved materials for freeze-thaw cycles

- Better integration with urban water management

Material Innovations

Developing materials offer:

- Improved durability and lifespan

- Better load-bearing capacity

- Enhanced filtration properties

- Recycled content options

Frequently Asked Questions

Do I need planning permission for permeable paving?

Generally no, if the paving allows water to drain naturally to a permeable area. Non-permeable paving over 5m² typically requires planning permission unless it drains to a permeable area within your property boundary.

How long does permeable paving last?

Well-maintained permeable paving typically lasts 20-25 years. The surface may need renovation or partial replacement during this period, but the sub-base structure often remains serviceable longer.

Can permeable paving handle heavy vehicles?

Yes, properly designed and installed permeable paving can handle standard vehicle loads including delivery trucks. Commercial applications may require specialist design for heavier loads.

What happens if permeable paving gets blocked?

Blocked permeable paving can usually be restored through professional cleaning. Vacuum equipment removes debris from joints, and pressure washing can clear surface pores. Severely blocked systems may need joint sand replacement.

Is permeable paving more expensive than regular paving?

Initial installation costs are typically 20-50% higher than non-permeable alternatives. However, you may save on drainage infrastructure and avoid planning permission costs.

Can I install permeable paving on clay soil?

Clay soil can be challenging for permeable paving due to poor drainage. You may need to install additional drainage systems or modify the sub-base design. Professional assessment is recommended.

Does permeable paving work in winter?

Yes, permeable paving generally performs well in winter. Better drainage can actually reduce ice formation compared to conventional paving where water pools on the surface.

How often does permeable paving need maintenance?

Basic maintenance (leaf removal, surface cleaning) should be done monthly. Professional deep cleaning is recommended annually, with joint sand replacement every 2-3 years as needed.

Can I retrofit my existing driveway to be permeable?

Retrofitting is possible but typically requires complete reconstruction to install the proper sub-base layers. It’s usually more cost-effective to plan permeable systems for new installations.

What’s the minimum slope needed for permeable paving?

Permeable paving works on slopes from 1:60 (1.7%) to 1:10 (10%). Flatter slopes may need additional drainage provision, whilst steeper slopes may require specialist design.

Conclusion

Choosing between permeable and non-permeable paving depends on your specific situation, budget, and priorities.

Choose permeable paving if:

- You want to avoid planning permission for areas over 5m²

- Environmental benefits are important to you

- Your property has good natural drainage

- You’re willing to invest in regular maintenance

Choose non-permeable paving if:

- You need maximum durability for heavy use

- Maintenance must be minimal

- Your budget is tight

- You have poor natural drainage conditions

Both options can provide excellent long-term service when properly designed, installed, and maintained. Consider consulting with local contractors and checking your local authority’s planning and drainage requirements before making your final decision.

The key to success with either system is proper planning, quality installation, and appropriate ongoing maintenance. With good preparation, both permeable and non-permeable paving can add value and functionality to your property for decades to come.