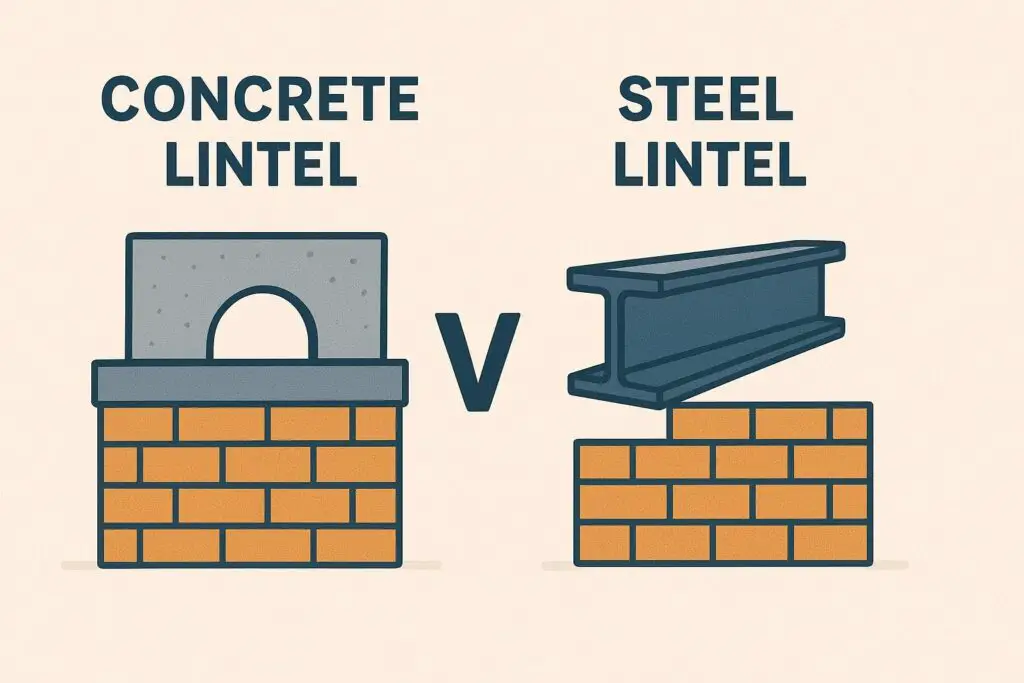

When you’re building or renovating, choosing between concrete and steel lintels affects your project’s cost, timeline, and long-term performance. Both materials excel in different situations, and your choice depends on factors like span width, load requirements, and building regulations.

Quick Answer: Concrete lintels work best for residential builds with spans under 1.5 metres, whilst steel lintels handle larger spans and heavier loads more effectively. Steel costs more upfront but offers superior strength-to-weight ratio.

What Are Lintels and Why Do They Matter?

Lintels are horizontal structural elements that span openings like doors and windows. They transfer the weight from above the opening to the supporting walls on either side.

Without proper lintels, you risk:

- Structural failure above openings

- Cracks in walls and frames

- Building regulation violations

- Expensive repairs later

The two main types are concrete (reinforced concrete) and steel, each with distinct advantages for different applications.

Concrete Lintels: Strengths and Limitations

What Are Concrete Lintels?

Concrete lintels consist of reinforced concrete with steel bars (rebar) for tensile strength. They’re cast either on-site or precast in factories.

Key Advantages of Concrete Lintels

Cost-Effective for Small Spans Concrete lintels typically cost 30-50% less than steel equivalents for residential applications. A standard 1200mm concrete lintel costs around £25-40, whilst steel versions start at £45-70.

Excellent Fire Resistance Concrete naturally resists fire better than steel. It won’t buckle under extreme heat, making it ideal for buildings requiring high fire ratings.

Thermal Properties Concrete provides better thermal mass and insulation than steel, reducing cold bridging through the structure.

Easy Installation Most builders are familiar with concrete lintel installation. No specialised welding or cutting equipment needed on-site.

Limitations of Concrete Lintels

Weight Constraints Concrete lintels are significantly heavier than steel. A 1.5m concrete lintel weighs approximately 50-80kg compared to 15-25kg for steel.

Limited Span Capability Concrete lintels work well for spans up to 1.5 metres. Beyond this, they become impractically heavy and may require additional support during installation.

Potential for Cracking Over time, concrete can develop hairline cracks, though this rarely affects structural integrity when properly installed.

Steel Lintels: Performance and Applications

What Are Steel Lintels?

Steel lintels are fabricated from galvanised steel sections, typically C-sections, T-beams, or box sections depending on the application.

Key Advantages of Steel Lintels

Superior Strength-to-Weight Ratio Steel lintels can span much larger distances whilst remaining lightweight. They’re essential for spans over 1.5 metres or heavy load applications.

Versatile Design Options Steel allows for complex shapes and custom fabrication. You can create lintels for unusual openings or architectural features.

Speed of Installation Lighter weight means faster installation with smaller crews. This reduces labour costs and project timelines.

Consistent Quality Factory-manufactured steel lintels offer predictable performance characteristics and consistent dimensions.

Limitations of Steel Lintels

Higher Initial Cost Steel lintels cost more upfront, though this often balances out over large spans where multiple concrete lintels would be needed.

Thermal Bridging Steel conducts heat efficiently, potentially creating cold spots in well-insulated walls. Proper thermal breaks are essential.

Corrosion Concerns Despite galvanising, steel can corrode if the coating is damaged during installation or over time in harsh environments.

Fire Performance Steel loses strength rapidly at high temperatures, potentially requiring additional fire protection in some applications.

Concrete Lintel vs Steel Lintel: Direct Comparison

| Factor | Concrete Lintel | Steel Lintel | Winner |

|---|---|---|---|

| Cost (up to 1.5m) | £25-40 | £45-70 | Concrete |

| Weight (1.5m span) | 50-80kg | 15-25kg | Steel |

| Maximum practical span | 1.5m | 6m+ | Steel |

| Fire resistance | Excellent | Requires protection | Concrete |

| Installation complexity | Simple | Simple | Draw |

| Thermal performance | Good insulation | Thermal bridging risk | Concrete |

| Durability | 50+ years | 25-40 years | Concrete |

| Customisation | Limited | High | Steel |

When to Choose Concrete Lintels

Ideal Applications for Concrete

Residential Construction Most homes have door and window spans under 1.5 metres, making concrete lintels perfect for:

- Standard door openings (900mm-1000mm)

- Single windows (up to 1.2m)

- Cavity wall construction

Budget-Conscious Projects When cost is the primary concern and spans are manageable, concrete offers excellent value.

Fire-Rated Construction Buildings requiring high fire ratings benefit from concrete’s natural fire resistance.

Building Regulation Considerations

Under UK Building Regulations Part A (Structure), both concrete and steel lintels must be properly designed for their loads. Concrete lintels typically satisfy requirements for:

- Standard residential loadings

- Spans up to 1.5m

- Normal exposure conditions

When to Choose Steel Lintels

Ideal Applications for Steel

Large Openings Steel becomes essential for:

- Wide patio doors (2m+)

- Large picture windows

- Commercial storefronts

- Open-plan internal openings

Heavy Load Situations When supporting:

- Multiple floors above

- Heavy roof structures

- Concentrated loads from beams

Tight Construction Schedules Steel’s lighter weight speeds installation, crucial for:

- Commercial projects with tight deadlines

- Restricted access situations

- Projects requiring crane lifts

Structural Engineering Requirements

Spans over 1.5m typically require structural engineer calculations regardless of material choice. Steel lintels often need specific design for:

- Load distribution

- Deflection limits

- Connection details

Installation Considerations

Concrete Lintel Installation

Preparation Steps:

- Ensure adequate bearing (minimum 100mm each end)

- Check wall alignment and level

- Plan lifting equipment for heavy units

- Verify cavity wall ties alignment

Common Installation Issues:

- Inadequate bearing length

- Poor mortar bedding

- Damage during lifting

- Incorrect damp-proof course positioning

Steel Lintel Installation

Key Installation Points:

- Handle carefully to avoid coating damage

- Ensure proper bearing on both ends

- Check alignment before fixing

- Install thermal breaks if required

Potential Problems:

- Galvanising damage during handling

- Inadequate end bearing

- Poor connection to supporting structure

- Thermal bridging through insulation

Cost Analysis: Total Project Impact

Initial Material Costs

Concrete Lintel Pricing (typical UK rates):

- 1.0m span: £20-30

- 1.2m span: £25-35

- 1.5m span: £35-50

Steel Lintel Pricing:

- 1.0m span: £40-60

- 1.2m span: £45-70

- 1.5m span: £55-85

- 2.0m span: £80-120

Hidden Cost Factors

Labour Considerations:

- Concrete: Requires more manpower for lifting

- Steel: Faster installation, potential crane costs for large units

Long-term Maintenance:

- Concrete: Minimal maintenance, potential repointing

- Steel: Monitor for corrosion, possible coating renewal

Performance in Different Environments

Coastal and High-Moisture Areas

Concrete Performance: Generally excellent in coastal conditions. The alkaline nature of concrete protects embedded steel reinforcement. Regular inspection of joints prevents water ingress.

Steel Performance: Requires high-quality galvanising or additional protective coatings. Marine-grade steel may be necessary in severe coastal environments.

Internal vs External Applications

Internal Use: Both materials perform well internally. Steel’s thermal bridging is less critical in internal walls.

External Use: Consider weather exposure, thermal movement, and building envelope performance. Concrete often integrates better with masonry construction.

Common Problems and Solutions

Concrete Lintel Issues

Problem: Hairline cracking Solution: Normal in concrete, monitor for progression. Seal if necessary.

Problem: Excessive weight during installation Solution: Use mechanical lifting aids, plan crew size accordingly.

Problem: Poor thermal performance Solution: Consider insulated concrete lintels or additional insulation details.

Steel Lintel Issues

Problem: Corrosion at cut ends Solution: Treat exposed steel with zinc-rich paint or similar protection.

Problem: Thermal bridging Solution: Install thermal breaks or consider composite lintels.

Problem: Deflection over time Solution: Ensure adequate structural design, consider pre-cambered sections.

Building Regulations and Standards

UK Compliance Requirements

Both lintel types must comply with:

- BS EN 845-2: Specification for ancillary components (including lintels)

- Building Regulations Part A: Structural requirements

- Part L: Conservation of fuel and power (thermal bridging)

Professional Design Requirements

Structural engineer input is typically required for:

- Spans over 1.5m

- Non-standard loadings

- Commercial applications

- Listed building modifications

The Institution of Structural Engineers provides guidance on when professional design is necessary.

Planning Permission Considerations

Most lintel installations don’t require planning permission, but consider:

- Listed building consent for historic properties

- Conservation area restrictions

- Permitted development limits for extensions

Making Your Decision: Key Questions

Assessment Framework

1. What’s the span requirement?

- Under 1.5m: Consider concrete

- Over 1.5m: Steel likely necessary

2. What are the load requirements?

- Standard residential: Concrete adequate

- Heavy loads/multiple floors: Steel preferred

3. What’s your budget constraint?

- Tight budget, short spans: Concrete

- Value engineering over time: Consider total project cost

4. What are the installation constraints?

- Limited access: Steel’s lighter weight helps

- Standard construction: Both suitable

5. What are the long-term requirements?

- Fire rating critical: Concrete advantage

- Minimal maintenance preferred: Concrete edge

Future-Proofing Your Choice

Adaptability Considerations

Steel Advantages:

- Easier to modify for future alterations

- Can support additional loads if properly designed

- Better for creating larger openings later

Concrete Advantages:

- Stable performance over decades

- No coating maintenance required

- Better integration with masonry construction

Technology Developments

Composite Lintels: New products combine steel strength with concrete thermal properties, though at premium pricing.

Insulated Options: Both steel and concrete now available with integrated insulation to address thermal bridging.

Regional Considerations Across the UK

Scotland

Stricter thermal regulations may favour concrete or require additional measures for steel lintels to prevent thermal bridging.

Wales

Similar requirements to England, but consider local stone and traditional construction methods in historic areas.

Northern Ireland

Check local building control requirements, which may vary from mainland UK standards.

Professional Resources and Support

Finding Qualified Installers

Structural Engineers:

- Institution of Structural Engineers member directory

- Local building control recommended lists

- Professional indemnity insurance verification

Specialist Suppliers:

- Catnic for steel lintels

- Local precast concrete suppliers for concrete options

- NHBC approved suppliers

Technical Support Resources

Manufacturer Support: Most manufacturers provide free technical support for:

- Load calculations

- Installation guidance

- Problem-solving assistance

Building Control Consultation: Early consultation with local building control prevents costly mistakes and delays.

Frequently Asked Questions

Can I replace a concrete lintel with steel?

Yes, but requires structural assessment. Steel’s different load distribution may need additional support points. Building control approval typically required.

How long do lintels last?

Concrete lintels: 50+ years with proper installation and minimal exposure to harsh conditions.

Steel lintels: 25-40 years depending on coating quality and environmental exposure.

Do I need planning permission to install new lintels?

Usually not for replacements or standard installations. Required for:

- Listed buildings (listed building consent)

- New openings in load-bearing walls

- Structural alterations affecting building stability

What happens if my lintel fails?

Signs include:

- Cracks above openings

- Doors/windows not closing properly

- Visible sagging

Immediate professional assessment required. Temporary support may be necessary before replacement.

Can I install lintels myself?

Possible for experienced DIYers on simple replacements, but consider:

- Structural implications

- Building control requirements

- Health and safety (especially weight of concrete lintels)

- Professional indemnity for errors

How do I calculate the correct lintel size?

Requires consideration of:

- Span width

- Load from above (walls, floors, roof)

- Bearing requirements

- Building regulations compliance

Professional calculation recommended for anything beyond simple residential applications.

What’s the environmental impact difference?

Concrete: Higher embodied carbon due to cement production, but longer lifespan.

Steel: Lower initial carbon footprint, but shorter replacement cycle may increase lifetime impact.

Can lintels be recycled?

Steel: Highly recyclable, valuable scrap material.

Concrete: Can be crushed for aggregate, but reinforcement complicates recycling.

Summary and Recommendations

Key Decision Points

Choose concrete lintels when:

- Spans are under 1.5 metres

- Budget is primary concern

- Fire resistance is critical

- Standard residential loading applies

- Long-term, low-maintenance solution preferred

Choose steel lintels when:

- Spans exceed 1.5 metres

- Heavy loads must be supported

- Installation speed is important

- Future modifications likely

- Precise structural performance needed

Final Recommendations

For most UK residential projects, concrete lintels provide excellent value and performance for standard door and window openings. Their lower cost, superior fire resistance, and minimal maintenance requirements make them the practical choice for spans under 1.5 metres.

Steel lintels become essential for larger spans, heavy loads, or situations requiring rapid installation. While more expensive initially, their superior strength-to-weight ratio and versatility justify the cost for demanding applications.

The decision ultimately depends on your specific project requirements. Consider total project costs, not just material prices, and always consult with structural engineers for anything beyond straightforward residential applications.

Both materials, when properly selected and installed, will provide decades of reliable service supporting your building’s openings. Choose based on your span requirements, load conditions, and project constraints rather than material preferences alone.

Remember that building regulations compliance is non-negotiable regardless of material choice. When in doubt, professional consultation ensures code compliance and optimal performance for your specific application.