Getting the cement mix ratio right for wall plastering makes the difference between a professional finish that lasts decades and a surface that cracks within months. Whether you’re a tradesperson perfecting your craft or a homeowner tackling a DIY project, understanding proper cement-to-sand ratios ensures your walls achieve optimal strength, durability, and appearance.

What is Wall Plastering?

Wall plastering involves applying a thin layer of cement mortar mixture onto wall surfaces to create a smooth, even finish. This process protects underlying masonry from weather elements whilst providing an ideal base for paint or decorative finishes. The cement mix ratio determines the strength, durability, and workability of the plaster.

Types of Wall Plastering

Modern construction employs several plastering techniques. Single coat plastering uses one layer of mortar, typically 12-15mm thick. Two coat plastering applies a rough base coat followed by a finishing coat. Three coat plastering includes a scratch coat, brown coat, and finish coat for superior results.

Standard Cement Mix Ratios for Different Applications

1:3 Cement Sand Mix Ratio

The 1:3 ratio provides maximum strength and durability. This mix uses one part cement to three parts sand, creating a robust plaster suitable for external walls and high moisture areas. The compressive strength reaches approximately 15-20 N/mm² after 28 days curing.

| Property | Value |

|---|---|

| Cement | 1 part |

| Sand | 3 parts |

| Water | 0.4-0.5 parts |

| Thickness | 12-20mm |

| Compressive Strength | 15-20 N/mm² |

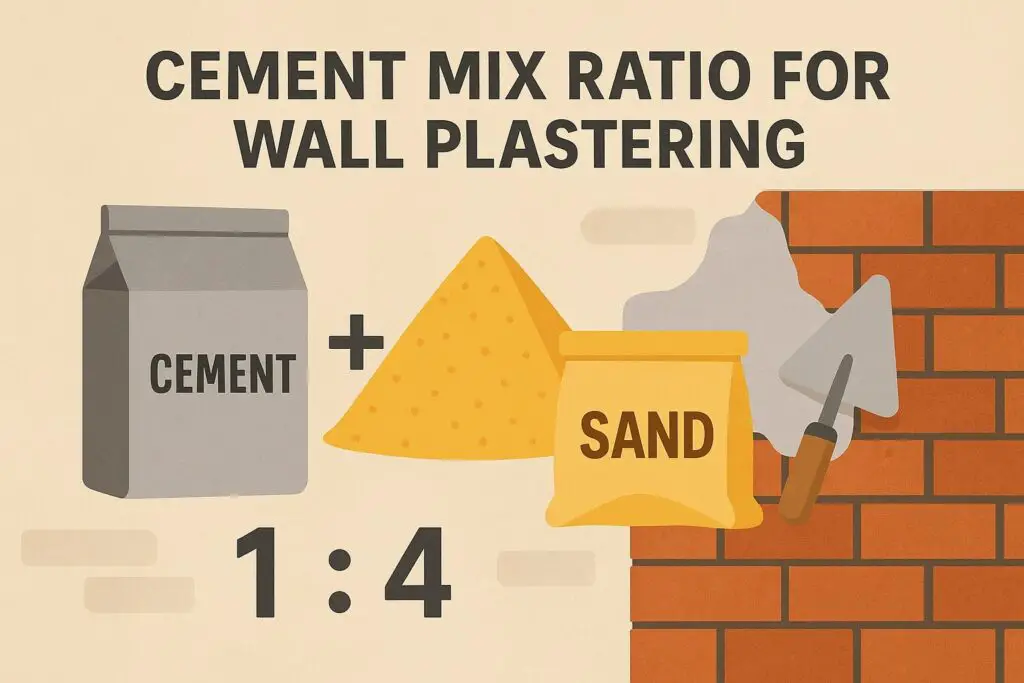

1:4 Cement Sand Mix Ratio

This balanced ratio offers excellent workability whilst maintaining adequate strength. One part cement mixed with four parts sand creates ideal conditions for internal wall finishing. The mixture provides good adhesion and smooth application properties.

1:5 Cement Sand Mix Ratio

The 1:5 ratio delivers economical plastering solutions for internal walls where high strength isn’t critical. This mix offers sufficient durability for residential applications whilst reducing material costs significantly.

1:6 Cement Sand Mix Ratio

Primarily used for internal plastering where loads are minimal, the 1:6 ratio maximises economy. However, this lean mix requires careful application to prevent cracking and ensure proper adhesion.

| Mix Ratio | Application | Strength | Cost |

|---|---|---|---|

| 1:3 | External walls, wet areas | High | High |

| 1:4 | General internal walls | Medium-High | Medium |

| 1:5 | Internal walls, dry areas | Medium | Low-Medium |

| 1:6 | Light internal plastering | Low-Medium | Low |

Factors Affecting Cement Mix Selection

Wall Surface Type

Brick walls typically require 1:4 or 1:5 ratios due to their porous nature. Concrete surfaces need stronger 1:3 mixes for proper adhesion. Stone walls may require varied ratios depending on stone type and surface preparation.

Environmental Conditions

Coastal areas demand stronger mixes (1:3) to resist salt corrosion. High humidity regions benefit from richer cement content. Dry climates allow leaner mixes without compromising durability.

Building Age and Structure

New constructions can accommodate any suitable ratio. Older buildings may require stronger mixes to compensate for structural movements. Heritage buildings often need specialised lime-cement combinations following conservation guidelines.

Materials Required for Wall Plastering

Cement Types and Selection

Ordinary Portland Cement (OPC)

OPC Grade 43 suits most plastering applications, offering rapid strength development. Grade 53 provides enhanced strength for demanding conditions but requires careful water management.

Portland Pozzolana Cement (PPC)

PPC offers superior workability and reduced heat of hydration. This cement type proves ideal for large wall areas and hot weather concreting conditions.

Sand Quality and Grading

River sand provides optimal results due to angular particles and cleanliness. The sand should pass through 4.75mm sieve completely, with 90% passing through 2.36mm sieve. Organic content must remain below 3% for proper cement hydration.

Water Requirements

Clean, potable water ensures proper cement hydration. The water-cement ratio typically ranges from 0.4-0.5 for optimal workability. Excessive water weakens the mix whilst insufficient water prevents proper hydration.

Step by Step Mixing Process

Preparation Phase

Begin by measuring materials accurately using volume or weight methods. Screen sand to remove debris and organic matter. Ensure mixing surface is clean and level for uniform distribution.

Mixing Techniques

Manual Mixing Method

Spread sand in a uniform layer, add cement proportionally, and dry mix thoroughly. Create a crater, add water gradually whilst mixing from outside to centre. Continue mixing until achieving uniform colour and consistency.

Machine Mixing Method

Load materials in correct sequence: half sand, all cement, remaining sand, then water gradually. Mix for 2-3 minutes until achieving homogeneous consistency. Machine mixing ensures better uniformity and reduces labour requirements.

Application Techniques for Different Mix Ratios

Internal Wall Plastering

Apply base coat using 1:4 or 1:5 ratio in 8-10mm thickness. Allow partial curing before applying finishing coat. Use float to achieve desired texture and levelness. Proper curing prevents cracking and ensures strength development.

External Wall Plastering

External surfaces require 1:3 or 1:4 ratios for weather resistance. Apply in two coats with total thickness 15-20mm. First coat should be rough to improve adhesion. Second coat provides smooth finish and weather protection.

| Location | Base Coat Ratio | Finish Coat Ratio | Total Thickness |

|---|---|---|---|

| Internal Dry Areas | 1:5 | 1:6 | 12-15mm |

| Internal Wet Areas | 1:4 | 1:5 | 15-18mm |

| External Protected | 1:4 | 1:5 | 15-20mm |

| External Exposed | 1:3 | 1:4 | 18-25mm |

Common Problems and Solutions

Cracking Issues

Hair cracks result from rapid drying or excessive water content. Control curing conditions and maintain proper water-cement ratios. Map cracking indicates structural movement requiring flexible repair methods.

Poor Adhesion Problems

Inadequate surface preparation causes bonding failure. Clean surfaces thoroughly and apply bonding agents where necessary. Dampening walls before application improves adhesion significantly.

Surface Defects

Dusting surfaces indicate weak mix ratios or poor curing. Efflorescence appears due to soluble salts migration. Proper material selection and curing practices prevent most surface defects.

Quality Control and Testing

Workability Tests

Flow table tests determine mix consistency and workability. Proper flow values range between 100-150mm for plastering applications. Adjust water content to achieve desired workability without compromising strength.

Strength Assessment

Cube tests evaluate compressive strength after 7 and 28 days. Standard plastering mixes should achieve minimum 5 N/mm² strength. Regular testing ensures quality compliance and identifies mixing issues early.

Cost Analysis and Material Estimation

Calculate material requirements based on wall area and plaster thickness. Include 5-10% wastage factor for accurate estimation. Labour costs vary with complexity and local rates but typically equal material costs.

| Wall Area | Cement (50kg bags) | Sand (cubic metres) | Estimated Cost |

|---|---|---|---|

| 100m² (1:4 ratio) | 8-10 bags | 1.2-1.5 m³ | £300-400 |

| 100m² (1:5 ratio) | 6-8 bags | 1.2-1.5 m³ | £250-350 |

Labour productivity averages 8-12m² per day for experienced plasterers. Complex surfaces or detailed work reduces coverage significantly.

Best Practices for Professional Results

Maintain consistent mixing procedures throughout the project. Use mechanical mixers for large areas to ensure uniformity. Apply plaster in manageable sections to prevent joint marks. Cure properly using water spraying or covering with damp cloth.

Weather conditions significantly impact results. Avoid plastering during extreme temperatures or high winds. Protect fresh plaster from direct sunlight and rain for optimal curing.

Maintenance and Longevity Tips

Regular inspection identifies problems before major repairs become necessary. Address cracks promptly to prevent water penetration. Reapply surface treatments as recommended by British Standards for maximum longevity.

Proper drainage prevents moisture-related deterioration. Maintain building envelope integrity through regular maintenance programmes. Quality initial application significantly reduces long-term maintenance requirements.

Conclusion

Selecting appropriate cement mix ratios for wall plastering ensures durable, attractive finishes that stand the test of time. The 1:4 ratio serves most internal applications effectively, whilst 1:3 ratios suit external or high-stress environments. Proper material selection, mixing techniques, and application methods determine success more than mix ratios alone.

Quality control throughout the process prevents common problems and ensures professional results. Regular maintenance and proper curing extend plaster life significantly. Understanding these principles enables both professionals and DIY enthusiasts to achieve excellent plastering results consistently.

Frequently Asked Questions

What is the best cement mix ratio for bathroom wall plastering?

Use a 1:3 or 1:4 cement sand ratio for bathroom walls due to high moisture conditions. The stronger mix provides better water resistance and prevents cracking from humidity changes. Apply waterproof additives for enhanced protection.

How much water should I add to cement plaster mix?

Add water to achieve a paste-like consistency, typically 0.4-0.5 times the cement weight. Too much water weakens the mix whilst insufficient water prevents proper workability. Add water gradually during mixing for best results.

Can I use the same mix ratio for both internal and external walls?

External walls require stronger mixes (1:3 or 1:4) compared to internal walls (1:4 to 1:6) due to weather exposure. Different environmental conditions demand specific mix designs for optimal performance and longevity.

What thickness should cement plaster be for different wall types?

Brick walls typically need 12-15mm thickness, concrete walls require 8-12mm, and stone walls may need 15-20mm depending on surface irregularities. Maintain consistent thickness for uniform appearance and performance.

How long should cement plaster cure before painting?

Allow cement plaster to cure for minimum 14-21 days before applying paint. Proper curing ensures strength development and prevents paint failure. Maintain moisture during initial curing period for optimal results.