Internal wall insulation transforms cold, draughty homes into comfortable, energy-efficient spaces whilst reducing heating bills significantly. This comprehensive guide explores proven insulation methods, materials, and installation techniques that deliver exceptional thermal performance for UK properties.

Explaining Internal Wall Insulation

What is Internal Wall Insulation?

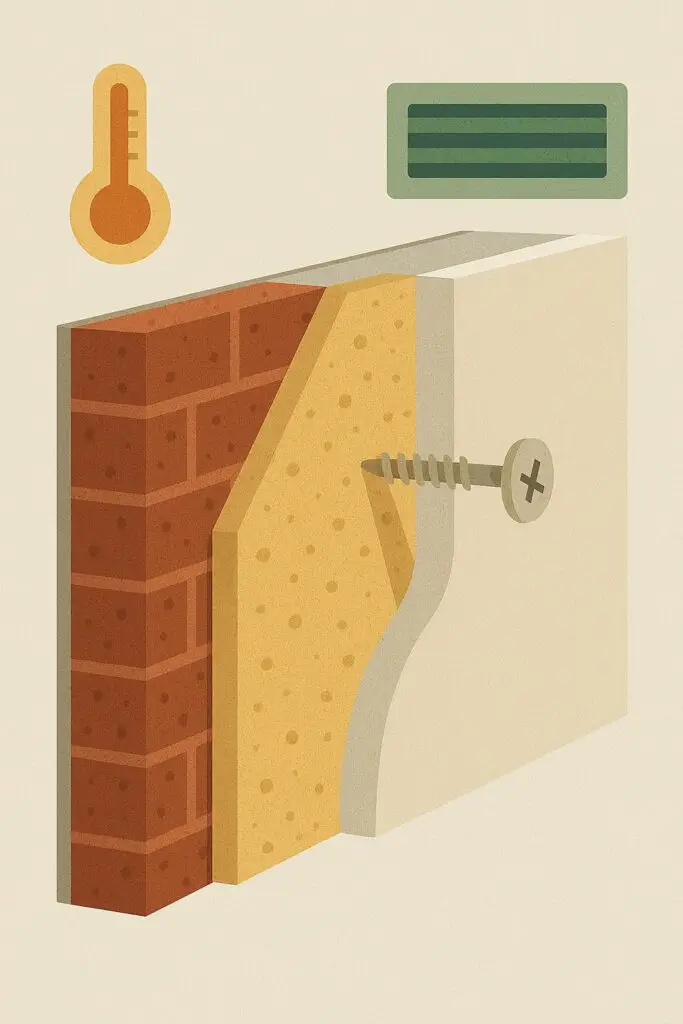

Internal wall insulation involves applying insulating materials to the interior surfaces of external walls. This method creates a thermal barrier that prevents heat loss through solid masonry walls, particularly effective for properties built before 1930 when cavity walls weren’t standard construction practice.

The system works by adding an insulation layer between the existing wall and interior living space. Modern internal wall insulation systems typically achieve U-values between 0.18-0.30 W/m²K, representing substantial improvements over uninsulated solid walls that commonly register 2.1 W/m²K.

Benefits of Internal Wall Insulation

Internal wall insulation delivers multiple advantages for homeowners seeking improved thermal comfort and reduced energy consumption. Primary benefits include:

Energy savings reach 25-35% on heating bills through reduced heat loss. Properties with internal wall insulation maintain consistent indoor temperatures with less heating system operation.

Enhanced comfort results from eliminated cold spots and draughts. Internal surfaces remain warmer, reducing radiant heat loss from occupants and creating more comfortable living conditions.

Rapid installation makes internal systems attractive compared to external alternatives. Most installations complete within 3-7 days depending on property size and complexity.

Cost effectiveness positions internal insulation as the most economical option for solid wall properties, typically costing £40-80 per square metre compared to £100-150 for external wall insulation.

When to Choose Internal Over External Insulation

Internal wall insulation becomes the preferred solution in specific circumstances. Listed buildings where external appearance must remain unchanged benefit from internal systems that preserve original facades whilst improving thermal performance.

Properties with limited external access, such as terraced houses or flats, often require internal solutions due to scaffolding restrictions or shared walls. Planning permission requirements frequently favour internal systems that don’t alter building exteriors.

Budget constraints make internal insulation attractive for homeowners seeking immediate thermal improvements without substantial capital investment. The lower material and labour costs enable phased installation across different rooms over time.

Types of Internal Wall Insulation Systems

Rigid Foam Board Insulation

Rigid foam boards represent the most common internal wall insulation approach, offering excellent thermal performance with minimal thickness. These systems bond directly to existing walls or fix mechanically using specialised fasteners.

Expanded polystyrene (EPS) boards provide cost-effective insulation with thermal conductivity values around 0.032-0.038 W/mK. Standard thicknesses range from 50mm to 150mm, with 100mm boards achieving U-values of approximately 0.30 W/m²K.

Polyurethane foam boards deliver superior thermal performance with conductivity values as low as 0.022 W/mK. Thinner boards achieve equivalent performance to thicker alternatives, crucial for properties where internal space preservation matters.

Phenolic foam boards offer the highest thermal performance available, with conductivity values reaching 0.018 W/mK. These premium materials maximise insulation effectiveness whilst minimising thickness requirements.

| Material Type | Thermal Conductivity (W/mK) | 100mm Thickness U-Value | Typical Cost (£/m²) |

|---|---|---|---|

| EPS Board | 0.032-0.038 | 0.30-0.35 | £15-25 |

| Polyurethane | 0.022-0.028 | 0.20-0.25 | £25-40 |

| Phenolic Foam | 0.018-0.022 | 0.16-0.20 | £35-55 |

Flexible Blanket Insulation

Flexible insulation materials suit irregular wall surfaces and cavities between timber studs in refurbishment projects. These systems accommodate building movement and uneven surfaces better than rigid alternatives.

Mineral wool blankets provide fire resistance and acoustic benefits alongside thermal insulation. Glass wool and rock wool variants offer thermal conductivity around 0.032-0.040 W/mK with excellent durability characteristics.

Natural fibre blankets include sheep’s wool, hemp, and recycled materials that appeal to environmentally conscious homeowners. These materials typically achieve thermal conductivity values between 0.035-0.045 W/mK.

Cavity Wall Insulation Fill

Properties with narrow cavities benefit from specialised fill materials that maximise thermal performance within limited space. These systems suit existing cavity walls requiring thermal improvement.

Blown mineral wool fills cavities completely, eliminating thermal bridging through wall ties. Professional installation ensures consistent density and thermal performance throughout the cavity.

Polystyrene bead systems with adhesive create stable cavity fill that won’t settle over time. These systems achieve excellent thermal performance whilst maintaining moisture permeability.

Reflective Foil Insulation

Multi-foil reflective systems combine thin insulation layers with reflective surfaces to create compact thermal barriers. These systems suit space-constrained applications where thickness limitations restrict conventional insulation.

Multi-layer foil systems typically measure 20-50mm thick whilst claiming equivalent performance to much thicker conventional insulation. However, performance depends heavily on correct installation with appropriate air gaps.

Popular Internal Wall Insulation Materials

Expanded Polystyrene (EPS) Boards

EPS boards dominate the internal wall insulation market due to their balance of performance, cost, and ease of installation. Manufacturing processes create closed-cell foam structures that provide consistent thermal properties and moisture resistance.

Standard EPS grades achieve thermal conductivity between 0.032-0.038 W/mK, with premium grades reaching 0.030 W/mK. The material’s lightweight nature simplifies handling and installation whilst maintaining structural integrity over decades.

Grey EPS boards incorporate graphite particles that improve thermal performance by 15-20% compared to white alternatives. These enhanced products achieve conductivity values around 0.031 W/mK whilst maintaining competitive pricing.

Installation typically involves adhesive bonding with mechanical fixings for additional security. Standard board sizes of 1200mm x 600mm suit most wall dimensions whilst minimising joint quantities.

Polyurethane Foam Panels

Polyurethane insulation delivers superior thermal performance through its closed-cell structure and low thermal conductivity. These characteristics enable thinner installations that preserve interior space whilst achieving excellent U-values.

Rigid polyurethane boards manufactured with pentane blowing agents achieve thermal conductivity around 0.022-0.025 W/mK. Foil facings on both sides improve thermal performance and provide vapour control properties.

Spray-applied polyurethane creates seamless insulation layers that eliminate thermal bridging through joints. Professional application ensures consistent thickness and complete coverage around obstacles and irregular surfaces.

The material’s excellent adhesion properties enable direct bonding to most substrates without additional fixings. However, correct surface preparation ensures optimal bond strength and long-term performance.

Mineral Wool Insulation

Mineral wool products combine thermal insulation with fire resistance and acoustic benefits. Glass wool and rock wool variants suit different applications depending on performance requirements and budget considerations.

Glass wool insulation typically achieves thermal conductivity around 0.032-0.040 W/mK with excellent fire resistance properties. The material’s flexibility accommodates irregular surfaces and building movement without performance degradation.

Rock wool insulation offers superior fire resistance and higher density for improved acoustic performance. Thermal conductivity values range from 0.034-0.042 W/mK depending on density and manufacturing process.

Semi-rigid batts suit stud wall construction, whilst flexible rolls accommodate irregular cavities. Vapour-permeable properties allow moisture movement whilst maintaining thermal performance.

Natural Fibre Insulation Options

Natural insulation materials appeal to environmentally conscious homeowners seeking sustainable alternatives to synthetic products. These materials often provide additional benefits such as moisture regulation and low embodied energy.

Sheep’s wool insulation offers excellent thermal performance with conductivity around 0.035-0.038 W/mK. The material’s hygroscopic properties regulate indoor humidity whilst maintaining insulation effectiveness when slightly damp.

Hemp fibre insulation combines thermal performance with carbon sequestration benefits. Typical thermal conductivity ranges from 0.038-0.042 W/mK with excellent durability and pest resistance characteristics.

Cork board insulation provides sustainable insulation with thermal conductivity around 0.040-0.045 W/mK. The material’s natural properties resist moisture, pests, and fungal growth whilst maintaining performance over decades.

Installation Methods and Techniques

Direct Bond System Installation

Direct bonding represents the most straightforward internal wall insulation installation method. This technique involves applying adhesive to insulation boards and fixing them directly to existing walls without additional framework.

Surface preparation determines installation success and long-term performance. Walls require cleaning, repair of defects, and primer application where necessary. Uneven surfaces may need render application to create suitable bonding substrates.

Adhesive application follows manufacturer specifications for coverage patterns and curing times. Ribbon and dab techniques suit most applications, with full-bed adhesion reserved for critical areas or irregular substrates.

Board installation proceeds systematically from bottom to top, ensuring level installation and tight joints. Mechanical fixings supplement adhesive bonding for additional security, particularly important for heavier insulation materials.

Quality checks include verifying board alignment, joint sealing, and fixing adequacy. Professional installation tools such as laser levels and mechanical lifters improve installation quality and efficiency.

Mechanical Fixing Methods

Mechanical fixings provide primary or supplementary attachment for insulation boards where adhesive bonding alone proves insufficient. These systems suit various substrates and loading conditions.

Plastic anchor fixings with thermal break properties minimise thermal bridging through the insulation layer. Standard fixings accommodate insulation thicknesses from 50mm to 200mm with appropriate holding power for most applications.

Helical fixings provide excellent pull-out resistance in solid masonry walls. The fixing design allows installation through insulation boards into substrate walls without pre-drilling.

Frame anchor systems suit heavy or thick insulation installations requiring additional support. These systems distribute loads across larger areas whilst maintaining thermal performance.

Fixing quantities depend on insulation type, thickness, and substrate conditions. Typical requirements range from 4-8 fixings per square metre for standard applications.

Stud Wall Construction Approach

Stud wall systems create insulated cavities between new internal frameworks and existing walls. This approach suits extensive refurbishment projects or situations requiring services integration.

Timber stud construction uses treated timber members at 400mm or 600mm centres. Insulation fits between studs with continuous layers behind the framework eliminating thermal bridging.

Metal stud systems provide straight, consistent frameworks with excellent fire resistance. Thermal break accessories minimise heat transfer through the metal framework whilst maintaining structural integrity.

Service integration becomes straightforward with stud wall systems accommodating electrical wiring, plumbing, and mechanical services within the insulated cavity. This approach eliminates thermal bridging through service penetrations.

Plasterboard finishing creates smooth internal surfaces ready for decoration. Vapour control layers may be necessary depending on insulation type and building requirements.

Performance Comparison and Cost Analysis

Thermal Performance Ratings

Understanding thermal performance enables informed material selection based on specific requirements and constraints. U-value calculations consider insulation thermal conductivity, thickness, and complete wall construction.

Baseline performance for uninsulated solid walls typically ranges from 1.8-2.4 W/m²K depending on wall thickness and construction. These values represent substantial heat loss requiring significant heating energy.

Insulated performance improvements depend on insulation type and thickness. Standard 100mm installations achieve U-values between 0.25-0.35 W/m²K, representing 85-90% thermal performance improvement.

Premium systems with advanced insulation materials achieve U-values below 0.20 W/m²K. These installations may require thicker materials or multiple layers but deliver maximum energy savings.

| Wall Construction | U-Value (W/m²K) | Heat Loss Reduction | Annual Saving* |

|---|---|---|---|

| Uninsulated 225mm Brick | 2.1 | Baseline | £0 |

| + 100mm EPS | 0.30 | 86% | £380-420 |

| + 100mm Polyurethane | 0.22 | 90% | £420-460 |

| + 100mm Phenolic | 0.18 | 91% | £440-480 |

*Based on typical semi-detached house, current energy prices

Installation Costs and ROI

Installation costs vary significantly based on material selection, property complexity, and installation approach. Understanding these factors enables realistic budgeting and payback calculations.

Material costs represent 40-60% of total project expense. Premium insulation materials command higher prices but deliver superior performance per unit thickness.

Labour costs depend on installation complexity and local rates. Direct bond systems require less labour than stud wall constructions but demand greater skill for quality results.

Additional costs include surface preparation, electrical modifications, and decorative finishing. These elements can significantly impact total project cost.

Return on investment calculations consider energy savings, comfort improvements, and property value increases. Typical payback periods range from 8-15 years depending on system specification and energy costs.

| System Type | Material Cost (£/m²) | Installation Cost (£/m²) | Total Cost (£/m²) | Payback Period |

|---|---|---|---|---|

| 100mm EPS Direct Bond | £15-25 | £25-35 | £40-60 | 10-12 years |

| 100mm Polyurethane | £25-40 | £25-35 | £50-75 | 8-10 years |

| Stud Wall + Mineral Wool | £20-30 | £35-50 | £55-80 | 12-15 years |

Maintenance Requirements

Internal wall insulation systems require minimal ongoing maintenance when correctly installed. Understanding maintenance needs helps preserve performance and maximise system lifespan.

Routine inspections should identify potential issues such as moisture ingress, thermal bridging, or mechanical damage. Annual visual checks suffice for most installations.

Moisture management remains critical for long-term performance. Proper ventilation and condensation control prevent insulation degradation and associated problems.

Surface protection through appropriate decorative finishes protects insulation from mechanical damage and moisture penetration. Regular redecoration maintains this protection.

System repairs may become necessary following building alterations or accidental damage. Professional assessment ensures repairs maintain system integrity and performance.

Building Regulations and Standards

UK Building Regulations Compliance

Building Regulations Part L sets thermal performance standards for new construction and major refurbishments. Understanding these requirements ensures compliant installations that meet current standards.

Approved Document L specifies maximum U-values for different building elements. New extensions require wall U-values no greater than 0.28 W/m²K, whilst renovations should achieve 0.30 W/m²K where reasonably practicable.

Consequential improvements may be required for extensions exceeding 100m² or 25% of existing floor area. These improvements often include internal wall insulation to existing elements.

Building Control approval ensures installations meet regulatory requirements. Approved installers can self-certify work under competent person schemes, simplifying the approval process.

Energy Performance Certificates reflect insulation improvements through improved ratings. Internal wall insulation typically improves EPC ratings by 1-2 bands depending on other property characteristics.

Documentation requirements include U-value calculations, material specifications, and installation certificates. These documents support EPC assessments and provide warranty protection.

Energy Performance Certificates

EPC ratings quantify building energy efficiency on scales from A (most efficient) to G (least efficient). Internal wall insulation contributes significantly to improved ratings and associated benefits.

Rating improvements typically range from 15-25 points on the SAP score depending on existing performance and insulation specification. Properties near band boundaries may achieve full band improvements.

Market benefits include enhanced property values and improved marketability. Research indicates insulated properties sell faster and command price premiums compared to uninsulated equivalents.

Rental market advantages become increasingly important as minimum energy efficiency standards rise. Properties below EPC band E cannot be let from 2025 unless exemptions apply.

Common Challenges and Solutions

Condensation and Moisture Management

Condensation risks increase with internal wall insulation due to changed thermal dynamics and potential vapour trapping. Understanding these risks enables effective prevention strategies.

Interstitial condensation occurs when warm, moist air penetrates insulation and condenses on cold surfaces within the wall construction. This phenomenon can cause insulation degradation and structural damage.

Vapour control layers prevent moisture penetration into insulation systems. These membranes must be continuous and properly sealed around penetrations to maintain effectiveness.

Thermal bridging through wall ties, lintels, and structural elements creates cold spots where condensation may occur. Specialist details address these thermal bridges whilst maintaining structural integrity.

Ventilation improvements often accompany insulation installations to manage increased air tightness. Mechanical ventilation systems ensure adequate air change rates whilst recovering heat from extract air.

Thermal Bridging Prevention

Thermal bridges create paths for heat loss that bypass insulation systems. Identifying and addressing these bridges maximises insulation effectiveness and prevents condensation risks.

Structural elements such as concrete lintels and steel beams penetrate insulation layers creating significant thermal bridges. Specialist insulation details minimise heat transfer through these elements.

Window and door reveals require careful detailing to maintain insulation continuity. Proprietary reveal systems extend insulation around openings whilst maintaining weatherproofing.

Service penetrations for electrical and plumbing systems create thermal bridges requiring sealing. Specialist products maintain air tightness whilst accommodating service requirements.

Junction details between walls, floors, and ceilings need careful design to maintain insulation continuity. Standard details address common situations whilst bespoke solutions suit unusual circumstances.

Space Reduction Considerations

Internal wall insulation reduces interior dimensions, potentially affecting room sizes and door/window positions. Planning for these changes ensures successful installations.

Room size impacts depend on insulation thickness and room dimensions. Typical 100mm systems reduce room dimensions by 100-120mm per external wall including finishes.

Door and window modifications may be necessary to accommodate reduced reveals. New door linings and window boards maintain aesthetic consistency whilst accommodating insulation systems.

Radiator repositioning ensures adequate clearances and maintains heating effectiveness. Extended brackets or slimline radiators accommodate reduced wall dimensions.

Built-in furniture may require modification or replacement to fit reduced room dimensions. Early planning identifies affected items and potential solutions.

Professional Installation vs DIY

Professional installation ensures optimal performance, regulatory compliance, and warranty protection. However, competent DIY enthusiasts can successfully install certain systems with appropriate preparation and materials.

Professional advantages include specialist knowledge, proper tools, and installation warranties. Approved installers provide Building Control certification and insurance-backed guarantees protecting homeowner investments.

Quality assurance through professional installation minimises risks of condensation, thermal bridging, and performance shortfalls. Experienced installers identify potential issues and implement appropriate solutions.

DIY considerations include skill requirements, tool availability, and regulatory compliance. Simple direct-bond systems suit capable DIY installers, whilst complex installations require professional expertise.

Cost savings through DIY installation can reach 40-60% of total system cost. However, mistakes may prove expensive to rectify and could void material warranties.

Training courses and manufacturer support help DIY installers achieve professional standards. Technical helplines and installation guides provide guidance throughout the installation process.

Maintenance and Longevity

Well-installed internal wall insulation systems provide decades of effective thermal performance with minimal maintenance requirements. Understanding system lifecycles and maintenance needs preserves performance and maximises return on investment.

Design life for quality insulation systems exceeds 25 years with appropriate maintenance. Premium materials and professional installation extend system lifecycles whilst maintaining performance.

Performance monitoring through energy consumption tracking identifies potential system degradation. Significant increases in heating requirements may indicate insulation problems requiring investigation.

Preventive maintenance includes regular visual inspections, ventilation system servicing, and prompt repair of any damage. These activities preserve system integrity and prevent minor issues becoming major problems.

System upgrades may become beneficial as technology advances or building requirements change. Modular systems enable partial upgrades whilst complete replacements suit major refurbishments.

Warranty provisions protect against premature failure and provide recourse for defective materials or installation. Understanding warranty terms and maintaining compliance preserves these protections.

Conclusion

Internal wall insulation transforms the thermal performance of solid wall properties whilst offering cost-effective solutions for improved comfort and reduced energy consumption. Modern systems deliver exceptional performance through advanced materials and proven installation techniques that address common challenges such as condensation and thermal bridging.

Selecting appropriate insulation methods depends on specific property requirements, budget constraints, and performance objectives. Direct bond systems using rigid foam boards suit most applications, whilst stud wall constructions accommodate complex refurbishments requiring services integration.

Professional installation ensures optimal performance and regulatory compliance, though competent DIY enthusiasts can successfully install simpler systems. Proper planning, quality materials, and attention to detail deliver long-lasting thermal improvements that enhance property values whilst reducing energy costs.

The investment in internal wall insulation typically pays for itself within 8-15 years through reduced energy costs, with additional benefits including improved comfort, enhanced property values, and reduced carbon emissions. As energy costs continue rising and environmental regulations tighten, internal wall insulation becomes increasingly attractive for property owners seeking sustainable thermal improvements.

Frequently Asked Questions

What is the most cost-effective internal wall insulation method?

Direct bond EPS board systems typically offer the best balance of cost and performance for most properties. These systems cost £40-60 per square metre installed and achieve excellent thermal performance with U-values around 0.30 W/m²K. The relatively simple installation process and proven long-term performance make EPS systems ideal for budget-conscious homeowners seeking significant thermal improvements.

How much room space will internal wall insulation reduce?

Standard 100mm internal wall insulation systems reduce room dimensions by approximately 110-120mm per external wall, including the insulation thickness and finishing materials. This reduction affects room sizes and may require modifications to door frames, window reveals, and radiator positions. Thinner high-performance materials such as phenolic foam can achieve similar thermal performance with 60-80mm thickness reduction.

Can internal wall insulation cause damp problems?

Properly designed and installed internal wall insulation systems do not cause damp problems when appropriate vapour control and ventilation measures are implemented. However, poor installation or inadequate moisture management can create condensation risks. Professional installation includes vapour barriers, thermal bridge elimination, and ventilation assessments to prevent moisture-related issues whilst maintaining thermal performance.

How long does internal wall insulation installation take?

Installation timeframes depend on property size and system complexity. Direct bond systems typically require 2-4 days for average three-bedroom houses, whilst stud wall constructions may take 5-7 days. Additional time is needed for surface preparation, electrical modifications, and decorative finishing. Professional installers provide accurate timeframes during initial assessments based on specific property requirements.

What building regulations approval is needed for internal wall insulation?

Internal wall insulation installations typically require Building Control notification under Building Regulations Part L. However, installations by approved contractors under competent person schemes can be self-certified without separate Building Control approval. Major refurbishments or extensions may trigger additional requirements including consequential improvements to existing building elements. Consulting with Building Control or approved installers ensures regulatory compliance and proper certification.