Imagine walking barefoot across your home on a cold winter morning, feeling warmth radiating up through the floor beneath your feet. This luxurious experience isn’t just for high end spas anymore. Hydronic floor heating has become an increasingly popular choice for homeowners seeking efficient, comfortable, and sustainable heating solutions.

This comprehensive guide explores everything you need to know about hydronic radiant floor heating systems, from how they work to installation costs, maintenance requirements, and long-term benefits. Whether you’re building a new home or renovating an existing property, understanding these systems will help you make an informed decision about your heating needs.

What is Hydronic Floor Heating?

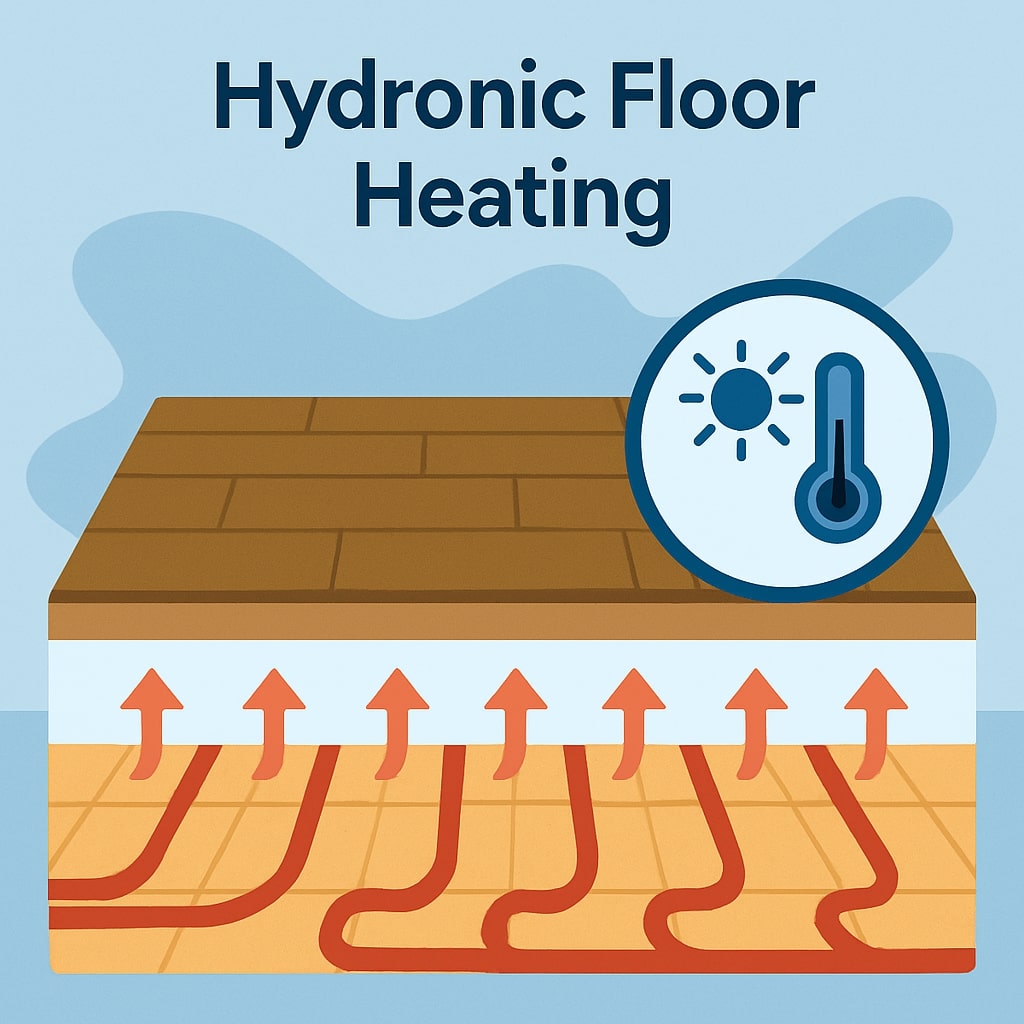

Hydronic floor heating, also known as wet underfloor heating, is a radiant heating system that circulates warm water through a network of pipes installed beneath your floor surface. Unlike traditional heating systems that warm the air, hydronic systems heat objects and surfaces directly, creating consistent, comfortable temperatures throughout your living space.

The system consists of a network of flexible pipes, typically made from cross linked polyethylene (PEX) or polybutylene, connected to a central heating source such as a boiler, heat pump, or solar collector. Water heated to temperatures between 35°C and 60°C flows through these pipes, transferring heat to the floor surface above.

This method of heating has been used for centuries, with ancient Romans utilising hypocaust systems to heat their buildings. Modern hydronic systems represent a sophisticated evolution of this concept, incorporating advanced materials, precise temperature controls, and energy efficient heat sources.

How Hydronic Floor Heating Works

The Science Behind Radiant Heat Transfer

Radiant heating operates on the principle of thermal radiation, where heat energy transfers directly from warmer surfaces to cooler objects and people. This process mimics how the sun warms the earth, creating a natural and comfortable heating experience.

When warm water flows through the pipe network, it heats the floor surface, which then radiates warmth upward. This creates an even temperature distribution from floor to ceiling, eliminating the hot and cold spots common with forced-air systems. The radiant heat warms your body directly, allowing you to feel comfortable at lower air temperatures.

System Components and Water Circulation

A complete hydronic floor heating system comprises several key components working together seamlessly:

| Component | Function | Key Features |

|---|---|---|

| Heat Source | Heats water for circulation | Boiler, heat pump, or solar collector |

| Manifold | Distributes water to different zones | Balancing valves and flow meters |

| Circulation Pump | Moves water through the system | Variable speed for efficiency |

| Pipes | Carry heated water under floors | PEX or polybutylene tubing |

| Controls | Regulate temperature and timing | Thermostats and zone valves |

| Insulation | Prevents heat loss downward | Rigid foam or reflective barriers |

The circulation pump moves heated water from the source through the manifold, which distributes it to individual heating zones. Each zone can be controlled independently, allowing precise temperature management throughout your home. After transferring its heat to the floor, the cooler water returns to the heat source for reheating, creating a continuous circulation loop.

Types of Hydronic Floor Heating Systems

Wet System Installation

Wet systems represent the most common installation method for hydronic floor heating. The heating pipes are embedded directly into a concrete screed or sand and cement mixture, creating excellent thermal mass and heat distribution.

During installation, the pipes are laid out in predetermined patterns across the floor area, secured with clips or mesh systems. A layer of screed, typically 65-75mm thick, is then poured over the pipes, completely encasing them. This thermal mass stores heat effectively and releases it gradually, maintaining consistent temperatures.

Wet systems work exceptionally well with tile, stone, and other hard floor finishes. The concrete screed provides excellent heat conduction and durability, making this method ideal for new construction or major renovations where floor height increases aren’t problematic.

Dry System Installation

Dry systems offer a lower profile alternative that doesn’t require concrete screeds. Instead, the heating pipes are installed within pre-formed grooves in insulation boards or between timber joists, with heat diffusion plates spreading the warmth across the floor surface.

These systems typically add only 15-25mm to floor height, making them suitable for retrofit projects where minimal disruption is essential. Installation is faster than wet systems, and the reduced thermal mass means quicker heat-up times, though temperature stability may be slightly less consistent.

Dry systems work well with wooden floors, laminate, and carpet installations. The heat diffusion plates ensure even temperature distribution despite the reduced thermal mass.

Suspended Floor Systems

Suspended floor systems install heating pipes beneath existing floors, typically in ceiling voids or purpose built channels. This method suits retrofit projects where accessing the floor surface from above isn’t practical or desirable.

The pipes are secured beneath the floor structure with insulation installed below to direct heat upward. While this method requires careful design to ensure adequate heat output, it offers minimal disruption to existing living spaces during installation.

Benefits of Hydronic Floor Heating

Energy Efficiency Advantages

Hydronic systems operate at significantly lower water temperatures than traditional radiator systems, typically between 35°C and 60°C compared to 70°C to 80°C for radiators. This lower operating temperature makes them ideal partners for high efficiency condensing boilers and heat pumps.

The even heat distribution reduces heat loss through stratification, where warm air rises to the ceiling in conventional systems. With radiant heating, the warmest area is at floor level where you need it most, improving overall system efficiency by up to 30% compared to forced air systems.

Modern hydronic systems can achieve seasonal efficiency ratings exceeding 90% when paired with appropriate heat sources. The ability to zone different areas independently further enhances efficiency by heating only occupied spaces when needed.

Comfort and Health Benefits

The gentle, consistent warmth from hydronic floor heating eliminates the temperature fluctuations common with conventional heating systems. There are no drafts, noise, or air circulation that can distribute dust, allergens, or bacteria throughout your home.

For individuals with allergies or respiratory conditions, hydronic heating provides significant advantages. The system doesn’t rely on air movement to distribute heat, reducing airborne particles and maintaining better indoor air quality. The consistent temperatures also help prevent condensation and moisture problems that can lead to mould growth.

The radiant heat keeps floors warm and comfortable for bare feet, making it particularly beneficial for bathrooms, kitchens, and children’s play areas. Many users report improved sleep quality due to the stable, comfortable temperatures maintained throughout the night.

Long-term Cost Savings

While hydronic systems require higher upfront investment than some alternatives, they offer substantial long-term savings through reduced energy consumption and minimal maintenance requirements. The embedded pipe systems typically last 50+ years, often outlasting the building structure itself.

Operating costs can be 20-40% lower than conventional heating systems, depending on your local energy costs and the efficiency of your heat source. The zoned control capabilities allow you to heat only occupied areas, further reducing energy waste.

Property values often increase with professionally installed hydronic floor heating systems, particularly in premium markets where comfort and efficiency are highly valued.

Installation Process and Requirements

Pre-installation Planning

Successful hydronic floor heating installation begins with comprehensive planning and design. Heat loss calculations determine the required heat output for each room, considering factors such as insulation levels, window areas, ceiling heights, and local climate conditions.

The pipe layout design ensures even heat distribution while minimising pressure drops and maintaining adequate flow rates. Typical pipe spacing ranges from 100mm to 300mm, with closer spacing in areas with higher heat requirements such as exterior walls and large windows.

Professional design software helps optimise pipe layouts, manifold locations, and control zones for maximum efficiency and comfort. This planning phase is crucial for system performance and should never be rushed or simplified.

Professional vs DIY Installation

While some enthusiastic DIYers attempt hydronic floor heating installation, the complexity of these systems generally requires professional expertise. Proper installation involves plumbing, electrical work, concrete work, and sophisticated controls integration.

Professional installers understand building regulations, have experience with various installation methods, and can provide warranties covering both labour and materials. They also have access to professional grade components and testing equipment essential for commissioning the system properly.

| Installation Aspect | Professional | DIY |

|---|---|---|

| Design Calculations | Comprehensive software tools | Basic online calculators |

| Component Selection | Trade pricing and warranties | Retail pricing |

| Installation Speed | 2-5 days typical | 2-4 weeks typical |

| Warranty Coverage | Full system warranty | Component warranty only |

| Compliance Assurance | Guaranteed code compliance | Your responsibility |

Permits and Building Regulations

Most jurisdictions require building permits for hydronic floor heating installations, particularly for new construction or major renovations. These permits ensure the installation meets local building codes, safety standards, and energy efficiency requirements.

Building regulations typically address insulation requirements, pipe materials and installation methods, electrical safety for pumps and controls, and integration with existing heating systems. Working with certified professionals ensures all regulatory requirements are met and documented properly.

Some areas offer rebates or incentives for high efficiency heating system installations, making professional installation more cost-effective while ensuring eligibility for available programs.

Hydronic vs Electric Underfloor Heating

Performance Comparison

Both hydronic and electric underfloor heating systems provide comfortable radiant warmth, but they differ significantly in performance characteristics, costs, and suitable applications.

Hydronic systems excel in larger areas and whole house installations, offering superior energy efficiency and lower operating costs over time. The thermal mass of hydronic systems provides better temperature stability and heat retention.

Electric systems suit smaller areas, retrofit bathrooms, and applications where installation simplicity outweighs long-term operating costs. They heat up faster than hydronic systems but lack the thermal mass for consistent temperature maintenance.

| Feature | Hydronic | Electric |

|---|---|---|

| Initial Cost | Higher | Lower |

| Operating Cost | Lower | Higher |

| Installation Complexity | Complex | Simple |

| Heat-up Time | Slower | Faster |

| Temperature Stability | Excellent | Good |

| Lifespan | 50+ years | 20-25 years |

Cost Analysis

The cost comparison between hydronic and electric systems depends heavily on the installation size, local energy costs, and intended usage patterns. For areas larger than 40-50 square metres, hydronic systems typically offer better long-term value despite higher installation costs.

Electric systems make economic sense for small bathrooms, occasional use spaces, or situations where the complexity of hydronic installation isn’t justified. However, in regions with high electricity costs, even small electric systems can become expensive to operate.

Professional energy analysis considering your specific situation, local utility rates, and usage patterns provides the most accurate cost comparison for your particular application.

Best Floor Types for Hydronic Systems

Tile and Stone Flooring

Ceramic tile, natural stone, and porcelain represent ideal floor finishes for hydronic heating systems. These materials have excellent thermal conductivity, allowing efficient heat transfer from the embedded pipes to the room above.

The thermal mass of tile and stone helps store heat energy, maintaining comfortable temperatures even when the system cycles off. This thermal flywheel effect improves comfort and reduces energy consumption by minimising temperature fluctuations.

Installation requires careful attention to expansion joints and adhesive selection to accommodate thermal movement. Professional tile installers experienced with heated floors understand these requirements and can recommend appropriate materials and techniques.

Hardwood and Laminate Options

Wood flooring requires more consideration for hydronic installations due to its insulating properties and sensitivity to moisture and temperature changes. Engineered hardwood generally performs better than solid wood, offering improved dimensional stability.

The moisture content of wooden floors must be carefully controlled during and after installation. Gradual heat-up procedures help prevent excessive shrinkage, gaps, or warping. Maximum surface temperatures should be limited to protect the wood finish and dimensional stability.

High quality laminate flooring designed for use over radiant heating can provide an attractive, cost-effective option. Look for products specifically rated for underfloor heating with appropriate thermal resistance values.

Carpet Compatibility

Carpet and underlay combinations can work with hydronic floor heating, though careful selection is essential to avoid excessive insulation that impedes heat transfer. The total thermal resistance (tog rating) should not exceed 2.5 for adequate system performance.

Natural fibres and low-profile carpets generally perform better than thick, synthetic options. Specialised underfloor heating underlays designed for radiant systems help optimise heat transfer while providing necessary cushioning.

Regular carpet maintenance becomes more important with underfloor heating, as dust and debris can affect thermal performance. Professional cleaning helps maintain both carpet appearance and heating efficiency.

System Costs and Budget Planning

Initial Installation Costs

Hydronic floor heating installation costs vary significantly based on system type, area size, access conditions, and local labour rates. Professional installation typically ranges from £50-£150 per square metre, including materials and labour.

Wet system installations generally cost more due to the screeding requirements and increased labour time. Dry systems offer cost savings through faster installation and reduced materials, though component costs may be higher.

Additional costs include the heat source (boiler or heat pump), manifolds and controls, electrical connections, and any necessary building modifications. Budget an additional 20-30% beyond the basic installation for these supplementary requirements.

| Cost Component | Typical Range (£/m²) | Notes |

|---|---|---|

| Wet System Installation | £80-£150 | Includes screed and labour |

| Dry System Installation | £60-£120 | Faster installation |

| Heat Source | £2,000-£8,000 | Boiler or heat pump |

| Controls and Manifolds | £300-£800 | Per zone |

| Professional Design | £500-£1,500 | Essential for performance |

Operating Expenses

Operating costs depend on your heat source efficiency, local energy prices, insulation levels, and usage patterns. Well designed hydronic systems typically cost £2-£4 per square metre annually to operate in moderate climates.

Gas-fired systems generally offer the lowest operating costs where natural gas is available and competitively priced. Heat pump systems can be more expensive to operate but offer environmental benefits and may qualify for renewable energy incentives.

Regular maintenance costs are minimal, typically involving annual system checks, occasional pump servicing, and preventive treatments to maintain water quality and prevent corrosion.

Return on Investment

Hydronic floor heating systems typically achieve payback periods of 8-15 years through energy savings, depending on the replaced heating system and local energy costs. Premium installations in high value properties may see immediate returns through increased property values.

The comfort and lifestyle benefits often justify the investment regardless of pure financial returns. Many homeowners consider the improved comfort, health benefits, and aesthetic advantages worth the premium costs.

Long system lifespans mean continued savings for decades after the payback period, making hydronic heating an excellent long-term investment for properties you plan to keep.

Maintenance and Troubleshooting

Regular Maintenance Tasks

Hydronic floor heating systems require minimal maintenance compared to conventional heating systems, but regular attention ensures optimal performance and longevity. Annual professional inspections help identify potential issues before they become costly problems.

The circulation pump requires periodic inspection and occasional servicing. Modern high efficiency pumps typically last 10-15 years with proper maintenance. Checking pump operation, cleaning filters, and ensuring proper circulation help maintain system efficiency.

Water quality management prevents corrosion and scaling within the pipe network. Adding inhibitors and biocides as recommended by manufacturers protects system components and maintains heat transfer efficiency.

| Maintenance Task | Frequency | Professional Required |

|---|---|---|

| System Pressure Check | Monthly | No |

| Visual Inspection | Quarterly | No |

| Professional Service | Annually | Yes |

| Water Quality Testing | Every 2-3 years | Recommended |

| Pump Service | Every 5-10 years | Yes |

Common Issues and Solutions

Most hydronic system problems relate to air in the system, circulation issues, or temperature control malfunctions. Proper installation and commissioning prevent many common problems, but understanding troubleshooting basics helps maintain system performance.

Air pockets can reduce circulation and create uneven heating. Automatic air vents and manual bleeding points help eliminate trapped air. Strange noises often indicate air in the system or pump problems requiring professional attention.

Temperature control issues may result from faulty thermostats, stuck zone valves, or calibration problems. These electronic components typically have 5-10 year lifespans and can be replaced without major system disruption.

Pipe leaks are rare in properly installed systems but can occur due to physical damage or poor installation practices. Professional leak detection equipment can locate problems without destructive investigation.

Energy Source Options

Gas Boilers

High efficiency condensing gas boilers represent the most popular heat source for hydronic floor heating systems in areas with natural gas availability. Modern condensing boilers achieve efficiencies exceeding 90% and work particularly well with the lower water temperatures required for radiant heating.

The consistent heat demand from floor heating systems allows boilers to operate in their most efficient range, maximising fuel economy and minimising emissions. Modulating burners adjust output to match heating demand precisely, further improving efficiency.

Combination boilers can provide both space heating and domestic hot water, simplifying installation and reducing equipment costs. However, separate dedicated heating boilers often provide better performance for larger installations.

Heat Pumps

Air source and ground source heat pumps offer renewable heating solutions that pair excellently with hydronic floor heating systems. The low water temperatures required for radiant heating allow heat pumps to operate at peak efficiency levels.

Ground source heat pumps achieve the highest efficiencies but require significant upfront investment for ground loop installation. Air source heat pumps offer easier installation and lower initial costs while still providing excellent efficiency.

Government incentives and renewable energy credits can significantly offset heat pump installation costs, making them increasingly attractive for new installations. Environmental benefits appeal to homeowners prioritising sustainability.

Solar Integration

Solar thermal collectors can supplement or provide primary heating for hydronic floor heating systems, particularly in mild climates or well insulated buildings. The thermal mass of floor heating systems helps store solar energy collected during sunny periods.

Integrated systems use solar collectors during favourable conditions and switch to backup heating sources when solar energy is insufficient. Sophisticated controls optimise the use of free solar energy while maintaining comfort requirements.

While solar heating systems require higher initial investment, they offer the ultimate in sustainable heating with minimal operating costs once installed.

Smart Controls and Thermostats

Modern hydronic floor heating systems benefit enormously from intelligent control systems that optimise comfort, efficiency, and convenience. Smart thermostats learn your schedule and preferences, automatically adjusting temperatures to maximise comfort while minimising energy consumption.

Zone based controls allow independent temperature management for different areas of your home, heating only occupied spaces when needed. Programmable schedules can reduce heating in unused areas or during periods when you’re away from home.

Smartphone apps and internet connectivity enable remote monitoring and control, allowing you to adjust settings from anywhere in the world. Some systems provide energy usage reporting and maintenance reminders to help optimise performance.

Weather compensation features adjust system operation based on outdoor temperatures, anticipating heating needs and maintaining consistent indoor comfort. These advanced controls can improve system efficiency by 10-20% compared to basic thermostats.

Integration with home automation systems creates comprehensive smart home experiences where heating works seamlessly with other building systems like lighting, security, and ventilation.

Environmental Impact and Sustainability

Hydronic floor heating systems offer significant environmental advantages compared to conventional heating methods. The improved efficiency reduces energy consumption and greenhouse gas emissions, particularly when combined with renewable heat sources.

The long lifespan of hydronic systems reduces waste and resource consumption over their operational life. Quality installations last 50+ years, eliminating the need for frequent equipment replacement that characterises some heating technologies.

Zoned heating capabilities reduce overall energy consumption by heating only occupied areas when needed. This targeted approach can reduce heating energy use by 20-30% compared to whole house heating systems.

The compatibility with renewable energy sources like heat pumps and solar thermal systems enables completely sustainable heating solutions. As electricity grids incorporate more renewable energy, even heat pump systems become increasingly environmentally friendly.

Indoor air quality benefits from hydronic heating include reduced dust circulation, elimination of ductwork contamination, and absence of combustion products in living spaces when using electric heat pumps.

Water heating systems can utilise waste heat from other sources, such as grey water heat recovery or industrial processes, further improving overall system sustainability and efficiency.

Conclusion

Hydronic floor heating represents a sophisticated, efficient, and comfortable heating solution that continues to grow in popularity among discerning homeowners. The combination of superior comfort, energy efficiency, and long-term reliability makes these systems an excellent investment for both new construction and renovation projects.

While the initial installation costs exceed conventional heating systems, the long-term benefits in comfort, efficiency, and property value often justify the premium investment. The minimal maintenance requirements and exceptional longevity ensure decades of reliable, comfortable heating with minimal ongoing costs.

The environmental benefits align with growing concerns about sustainability and energy conservation. As heat pump technology advances and renewable energy becomes more prevalent, hydronic floor heating systems will play an increasingly important role in sustainable building design.

Whether you’re building a new home, renovating an existing property, or simply seeking improved comfort and efficiency, hydronic floor heating deserves serious consideration. Professional consultation and design ensure optimal performance and help you realise the full benefits of this remarkable heating technology.

FAQs

What is the lifespan of a hydronic floor heating system?

Hydronic floor heating systems typically last 50+ years with proper installation and maintenance. The embedded pipes often outlast the building structure itself, while other components like pumps and boilers may require replacement every 15-20 years. The longevity makes hydronic systems one of the most durable heating options available.

Can hydronic floor heating work with existing flooring?

Existing flooring can often accommodate hydronic heating through dry system installations or suspended floor methods. However, some flooring types may need replacement to optimise performance. Professional assessment determines the best approach for your specific situation and flooring materials.

How much does it cost to run hydronic floor heating?

Operating costs typically range from £2-£4 per square metre annually, depending on your heat source, insulation levels, and local energy prices. Gas-fired systems usually offer the lowest operating costs, while heat pump systems provide environmental benefits despite potentially higher energy costs.

Is hydronic floor heating suitable for all room types?

Hydronic systems work well in most residential applications, including bathrooms, kitchens, living areas, and bedrooms. Special considerations apply to rooms with significant furniture coverage or areas requiring rapid temperature changes. Professional design ensures optimal performance for your specific room layouts and usage patterns.

What maintenance does hydronic floor heating require?

Maintenance requirements are minimal, involving annual professional inspections, periodic pump servicing, and water quality management. Most maintenance tasks are preventive and help ensure long-term system reliability. The embedded pipe network requires virtually no maintenance once properly installed and commissioned.